Antifragility and Aircraft Design

Nassim Nicholas Taleb coined the term “Antifragility” in his book of the same name. Antifragility describes objects that gain from random perturbations, i.e. disorder. Taleb writes,

Some things benefit from shocks; they thrive and grow when exposed to volatility, randomness, disorder, and stressors and love adventure , risk, and uncertainty. Yet, in spite of the ubiquity of the phenomenon, there is no word for the exact opposite of fragile. Let us call it antifragile. Antifragility is beyond resilience or robustness. The resilient resists shocks and stays the same; the antifragile gets better. This property is behind everything that has changed with time: evolution, culture, ideas, revolutions, political systems, technological innovation, cultural and economic success, corporate survival, good recipes (say, chicken soup or steak tartare with a drop of cognac), the rise of cities, cultures, legal systems, equatorial forests, bacterial resistance … even our own existence as a species on this planet. And antifragility determines the boundary between what is living and organic (or complex), say, the human body, and what is inert, say, a physical object like the stapler on your desk.

In greek mythology the sword of Damocles is an example of a fragile object as a single large blow will break it, a phoenix can resurrect and is therefore robust, while the Hydra is an antifragile serpent because for every head that is chopped off, two will grow back in its place. Antifragile systems are extremely important in complex environments where black swan events can wreak havoc. Black swans are rare but highly consequential events; the “fat tails” located far away from the mean in a probability distribution.

Often black swan events happen due to non-linear behaviour or a confluence of multiple drivers. Non-linearity is inherently difficult for our brains to comprehend which makes black swan events basically impossible to predict beforehand. In structural mechanics for example, it took researchers years to realise that the buckling behaviour of cylindrical shells, such as fuselage sections, is an inherently non-linear structural phenomenon, and that linear eigenvalue solutions could result in drastic over-predictions of the load carrying capacity. Theodore von Kármán managed to explain the physics of the problem through a series of papers in the first half of the 20th century, by first qualitatively investigating the phenomenon using simple experiments and then formalising the theory in what are now the non-linear von Kármán equations.

But what does this have to do with the engineering design process?

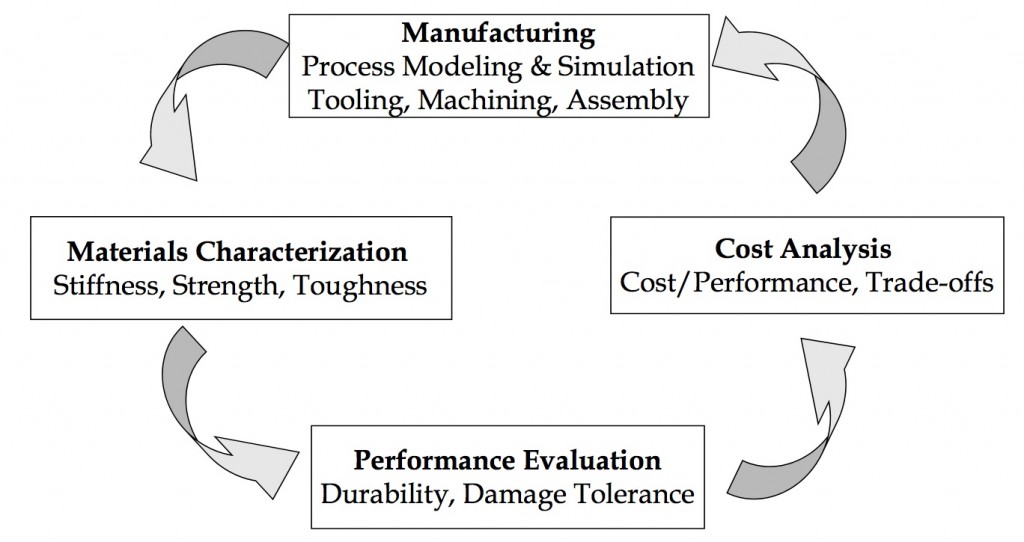

Well, by nature the design process is iterative. Ideally we strive towards creating a system of concurrent engineering. Tasks performed by the design, structural and manufacturing engineers are parallelised and integrated to reduce the development time to market, and reach the best compromise between different technical and financial requirements. Despite this parallelisation, the design process within each of these departments is still highly iterative as engineers across different functional fields interact and refine the design. Most importantly, throughout the whole aircraft design process individual components and sub-assemblies are experimentally tested to verify the design under critical load conditions. Examples of these are cabin section pressurisation fatigue tests and catastrophic tests of whole wing sub-assemblies. The information of these stress tests is fed back into the design system to close the loop and inform the next stage in the design.

Design Cycle (Courtesy of Wikipedia)

Taleb calls this form innovative work “stochastic tinkering”. It is a means of experimenting and adjusting a system, aiming to discover fact “A” but in the process also learning about “B”. Stochastic tinkering is by nature antifragile as good aspects of a design are retained while failures are quickly removed; very much an analog of the evolutionary process in nature.

Of course there is a good deal of deterministic analysis involved in engineering design. However, preliminary design calculations are often based on “back-of-the-envelope” methods. The aim of these preliminary calculations is to constrain the design space to a smaller feasible region. The design is then refined further in the detail design stage using more advanced techniques such as Finite Element Analysis or Computational Fluid Mechanics. Crucially, no matter how beautiful the design works on paper if it doesn’t perform in the validation tests it has failed.

Finally, the notion of designing for black swan events is inherently incorporated in the design process. In structural analysis of aircraft hundreds of different load cases are tested individually and in confluence to make sure the structure can withstand the worst imaginable/historic loading scenario multiplied by a factor of safety. Furthermore, the “safe-life”, “fail-safe” and “damage tolerant” design frameworks create a checklist for components which:

- are absolutely not allowed to fail during service (e.g. landing gear and wing root)

- are allowed to fail, as structural redundancies are in place to re-direct load paths (e.g. wing stringers and engines)

- and components that are assumed to contain a finite initial defect size before entering service that may grow due to fatigue loading in-service. In this manner the aircraft structure is designed to sustain structural damage without compromising safety up to a critical damage size that can be easily detected by visual inspection between flights.

This approach is limited to known load cases. Therefore, the reserve factors of 1.2 for limit load and 1.5 for ultimate load exist to provide a margin of safety against uncertainty, i.e. things we can not quantify, the “known unknowns” and “unknown unknowns”.

Historically, catastrophic in-service failures have been and continue to be used as invaluable learning experiences. Thus, “fat tail” catastrophic events are continually being used to eradicate weaknesses and improve the design. This, in essence, is the definition of antifragility. As terrible as the loss of life in the DeHavilland Comet and other crashes have been, without them, airplane travel would not be as safe as it is today.

Related Posts

Sign-up to the monthly Aerospaced newsletter

Recent Posts

- Podcast Ep. #49 – 9T Labs is Producing High-Performance Composite Materials Through 3D Printing

- Podcast Ep. #48 – Engineering Complex Systems for Harsh Environments with First Mode

- Podcast Ep. #47 – Möbius Aero and MμZ Motion: a Winning Team for Electric Air Racing

- Podcast Ep. #46 – Tow-Steered Composite Materials with iCOMAT

- Podcast Ep. #45 – Industrialising Rocket Science with Rocket Factory Augsburg

Topics

- 3D Printing (4)

- Aerodynamics (29)

- Aerospace Engineering (11)

- Air-to-Air Refuelling (1)

- Aircraft (16)

- Autonomy (2)

- Bio-mimicry (9)

- Case Studies (15)

- Composite Materials (25)

- Composites (7)

- Computational Fluid Dynamics (2)

- Contra-Rotation (1)

- Design (2)

- Digitisation (2)

- Drones (1)

- Education (1)

- Electric Aviation (11)

- Engineering (23)

- General Aerospace (28)

- Gliders (1)

- Helicopters (3)

- History (26)

- Jet Engines (4)

- Machine Learning (4)

- Manufacturing (12)

- Military (2)

- Modelling (2)

- Nanomaterials (2)

- NASA (2)

- New Space (11)

- News (3)

- Nonlinear Structures (1)

- Novel Materials/Tailored Structures (14)

- Personal Aviation (5)

- Podcast (45)

- Propulsion (9)

- Renewable Energy (2)

- Renewables (1)

- Rocket Science (17)

- Satellites (8)

- Shape Adaptation (1)

- Smart Materials (1)

- Space (12)

- Space Junk (1)

- Sport Airplanes (2)

- Startup (19)

- STOL (1)

- Structural Efficiency (5)

- Structural Mechanics (1)

- Superalloys (1)

- Supersonic Flight (2)

- Technology (18)

- UAVs (2)

- Virtual Reality (2)

- VTOL (3)

- Privacy & Cookies: This site uses cookies. By continuing to use this website, you agree to their use.

To find out more, including how to control cookies, see here: Cookie Policy