Understanding the details of the atmosphere is critical for manned flight since it provides the medium through which the aircraft moves. The lift provided by the wings and drag experienced by the aircraft vary greatly with different altitudes. In fact Sir Frank Whittle was largely motivated to design a jet engine due to his insight that aircraft would be able to fly faster and more efficiently at higher altitudes due to the lower density of air. The internal combustion engines at the time would not allow higher altitudes of flight, since the lack of oxygen was starving the engines thereby reducing power output.

In essence the atmosphere is a fluid skin that surrounds the entire earth to around 500 miles above the surface. Measured by volume the atmosphere at sea level is composed of 78% nitrogen, 20.9% oxygen, 0.9% Argon, 0.03% Carbon Dioxide and a trace of other gases. Up to about 50 miles the composition of the air is fairly constant, except for a variation in water vapour, which depends on the ambient temperature. The hotter the air the more water vapour it can hold (this is why you can see your breath on a cold morning as the cold air is saturated at this lower temperature). The heavier gases do not rise to high altitudes such that above 50 miles the atmosphere is largely comprised of hydrogen and helium. Above 18 000ft oxygen has depleted enough to prevent human’s from breathing and so oxygen is supplied mechanically to the cabin. At about 100 000ft oxygen is too low to allow combustion even in the most advanced turbojet engines.

In lower temperature latitudes the 36 000 ft of the atmosphere are generally known as the troposphere. In the troposphere the temperature decreases from about 20°C at sea level to -53°C. The tropopause is a hypothetical boundary between the lower troposphere and the higher stratosphere. In the stratosphere the temperature is initially constant and then increases to about -20°C at 35 miles. The separating tropopause is not a clear cut line but rather a hypothetical boundary that varies from around 30 000 ft over the poles to around 54 000 ft above the equator. As a result the temperature in the stratosphere is naturally warmer over the poles than over the tropics, since the higher altitude of the tropopause over the tropics allows the temperature to fall further before the constant temperature region of the stratosphere is reached. The atmosphere is divided further into regions such as the mesosphere, mesopause, thermosphere and the exosphere. However, these regions are outside of the realms of commercial and most fighter aircraft and we will therefore not deal with them here.

As originally observed by Sir Frank Whittle, the atmospheric conditions have a great effect on the performance of aircraft:

- The local ambient conditions of the air influence lift, drag and engine performance. In particular the pressure, density and temperature of the local air define the performance characteristics.

- The aircraft is moving relative to a fluid mass that in turn is moving relative to the surface of the earth. This introduces navigational problems that require special on-board equipment to control flight speed and direction.

- Temperature variations within the atmosphere may cause adverse weather patterns such as strong winds, turbulence, thunderstorms, heavy rain, snow, hail or fog. These criteria influence the loads applied on the aircraft, safety and the comfort of the passengers.

- The presence of the chemical compound ozone at high altitudes prevents cabin pressurisation with ambient air. This present the designer additional problems with air conditioning and prevention against pressure-cabin failure.

Air is a compressible fluid (i.e. it can change in volume and pressure in contrast to fluids which are largely incompressible). The compressibility of air allows it change shape and shear (flow) under the smallest pressure changes. The relation between pressure p, temperature T and volume v is governed by the ideal gas equation:

where R is the universal gas constant 287.07 J/kg/K and temperature is measured in Kelvin (T in °C + 273). In order to standardise calculations relating to the atmosphere the International Civil Aviation Organization has chosen a definition of the “standard atmosphere”. This states that air is a perfectly dry gas with a temperature at sea level of 15°C and 101.3 kPa of pressure. For the first 11 000km (i.e. in the troposphere) the temperature is assumed to change at a constant lapse rate of -6.5 °C/km, then stays constant at -56.5°C in the troposphere (11 000- 20 000 km) and then increases at different rates in the stratosphere. Another important metric for aircraft flight is the dynamic viscosity of “stickiness” of the air, which influences the drag imposed on the aircraft. You can imagine air being composed of thin layers of air that move relative to each other similar to multiple pieces of paper in a notebook. The dynamic viscosity is the constant of proportionality between the force per unit area required to shear the different sheets over each other and the velocity gradient between the layers. At ordinary pressures the dynamic viscosity generally depends only on the temperature of the air.

Finally the local atmospheric conditions is why aircraft engineers and pilots differentiate between the quantities of true airspeed (TAS), which is measured relative to the undisturbed air, and a fictional speed called the equivalent airspeed (EAS). The latter is of prime importance for aircraft design since it defines the forces that are acting on the aircraft. TAS and EAS are equivalent at sea level in the standard atmosphere but vary at altitude. As an aircraft moves through a mass of initially stationary air it imparts momentum to the surrounding air molecules by both impact and friction. The first molecules that hit the aircraft can be imagined to stick to the aircraft surface and are therefore stationary with respect to the aircraft. Every unit volume of air that has been accelerated to the velocity of the aircraft V, has therefore been imparted with a kinetic energy of

where q is known as the dynamic pressure. Aerodynamic quantities such as lift and drag are typically expressed as non-dimensional parameters i.e. they are divided by the wing area and the dynamic pressure to give the lift coefficient and drag coefficient.

The non-dimensional form of the parameters is important since it allows a performance comparison between different wings operating at different flying speeds or density conditions. Thus for an aircraft with a specific lift coefficient and wing area to generate the same aerodynamic forces at altitude as at sea level, the aircraft must be flown at a velocity that keeps the dynamic pressure a constant, regardless of any difference in air density. Thus, if the density at flying altitude is and the airspeed measured by the onboard controls is the TAS, then the equivalent speed at sea-level EAS with density

is defined by,

Therefore the EAS is a fictional quantity used in aerodynamic calculations to defined the speed that gives the same aerodynamic forces at sea-level as those experienced at altitude.

The treatment of defects in aircraft structural design has been an important aspect in aircraft structural design during the last 50 years. Various different catastrophic events have led to key insights that now shape the design philosophy for primary aircraft structures. One of these is the distinction between Safe-Life and Fail-Safe structures. Safe-Life components are designed to go through their service life without cracks and defects playing a major role in the stress state of the component. Thus, the required fatigue life to initiate a crack is kept below the anticipated service life. This design approach is mainly used for components for which there are no back-ups in place and where failure would lead to the loss of the aircraft. A typical example of a Safe-Life component is the landing gear and this remains one of the reasons why landing gears are made from high-strength steel for which engineers have a long history of structural data. The second “Fail-Safe” design philosophy assumes that any real manufacturing process will induce defects within the part that, even if microscopic, may vary between different batches and may grow during the service life. Thus the Fail-Safe components are structurally designed to withstand all imposed loads up to a certain certain level of defect, known as the “critical size”, which can usually be detected by eye and act as stress concentrators. In this manner critical components are continuously monitored at specific service intervals to make sure that no crack exceeds the critical defect size, and is subsequently replaced if this happens. Furthermore, crack propagation analyses are employed in order to ascertain how many flights/load cycles it will take to grow a crack to the critical size. Most of these insights stem from the experience engineers have gained during the last 50 years with metal aircraft and in fact there was quite a steep learning curve during the transition years from wood to metal aircraft.

Today we are facing a similar transition from metal to mostly fibre reinforced plastics and other advanced materials whose failure mechanisms are often much more complex than that of metals. First, in metallic structures a crack typically initiates at an imperfection or stress concentration and then propagates under fatigue loading until final failure. The damage morphology in composites however is completely different: a large number of microscopic defects, such as micro-cracks that occur during post-cure shrinkage of the resin are present over a large volume of the material and these may develop into different failure mechanism over time. Second, most metals have a ductile failure mechanism such that overloading can visually be detected by the onset of plastic deformation. Therefore there is often a warning period between a structure being overloaded and failing catastrophically. Fibre reinforced plastics, especially carbon fibre composites on the hand fail by more brittle and therefore sudden mechanisms. Third, while a major driver of component design for metal structures is crack growth, which can be predicted quite accurately today using analytical methods or Finite Element codes, fibre reinforced plastics have a plethora of other failure mechanisms and manufacturing defects that are equally important. Some examples are fibre breakage, matrix cracks, matrix-fibre debonding, delaminations, voidage, misplacement of plies, lack of impregnation and fibre waviness. Interlaminar failures such as delaminations are especially important since they can occur very quickly when a laminate is loaded through the thickness, for example at stringer run-outs, in corner-radii of C-spars or simple impact events such as tool drop in the factory. Since there are typically no reinforcing fibres in the perpendicular direction the structural integrity is only guaranteed by the weak matrix. Due to this inherent weakness different plies may literally be pulled apart at their lamination interfaces. Techniques such as through thickness reinforced such as 3D braiding, Z-Pinning or nano-fibre reinforcement are currently being researched. Under compressive forces these delaminations may form blisters, so called delimitation buckling, which can easily propagate along the lamination interface leading to disintegration of the part.

Finally, different failure mechanisms actually interact making accurate predictions of the failure load including a defect extremely difficult. Furthermore, even experimental data for laboratory sized specimens cannot readily be used for real-sized components since the scaling up of structures has been found to greatly alter the dominant failure mechanism. Finally, failure sites in fibre reinforced plastics are often internal meaning that an engineer will not be able to detect them by simple visual investigation during service intervals. As a result, the increasing use of fibre reinforced plastic construction during the recent years and near future means more sophisticated evaluation techniques are required for guaranteeing safe design and operation of aircraft. Another key question is how these new types of defects can be taken into account reliably in structural design?

Compared to metallic materials composites have a very unique characteristic in that the material and structure/part are created simultaneously. This means that the amount of imperfections in the part is greatly dependent on the manufacturing process. In composite materials the fail-safe design philosophy of degrading the material properties to that including a “critical defect size” is not only important to reduce the probability of failure as in metallic structures but also because a manufacturing process free from imperfections would be financially prohibitive. Thus, the degree of process and quality control depends greatly on the safety requirements of the industry. For example, the high-volume and competitive automobile sector needs to guarantee passenger safety while keeping manufacturing costs at a minimum. In the aerospace industry however the mass of components is absolutely critical and takes precedence over the manufacturing costs. As a result the automobile industry relies more on out-of-autoclave infusion processes that allow high production volumes such as Resin Transfer Moulding, while the aerospace industry currently relies on the high-temperature, high-pressure curing environments of the autoclave that allow the manufacture of high performance parts with low, controlled level of imperfections.

Non-destructive testing (NDT) methods are often employed to detect defects inside or on the surface of a material. In general they are broken down into surface methods, bulk volume methods and global methods. These methods are typically used at the end of the manufacturing process as a quality control measure or during the life of the part to monitor and assess its fitness for continuing use. Surface methods include visual inspection techniques such as scanning the surface for obvious cracks, porosities, resin rich/starved regions or surface waviness. This is often coupled with endoscopes to examine remote or difficult to access locations. Furthermore a common technique is dye penetrant inspection where a dye is applied to external surfaces and illuminated with an ultraviolet light in order to highlight cracks on the surface that the dye has crept into. This technique was quite popular for aero engine components but is inherently quite time and labour intensive.

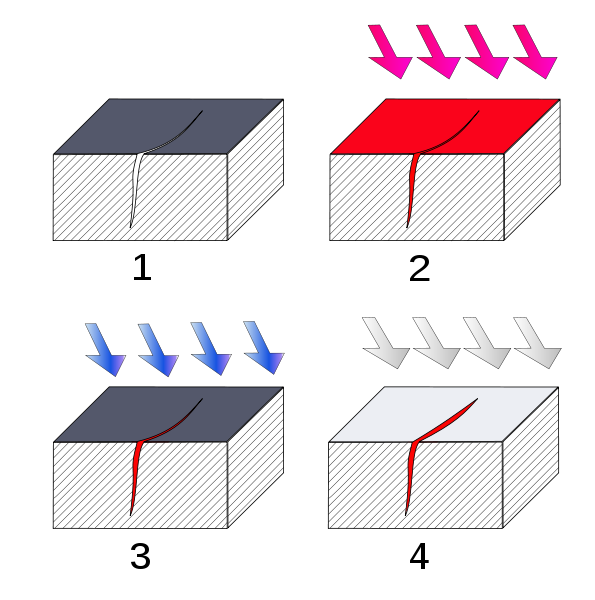

1. Section of material with a surface-breaking crack that is not visible to the naked eye.

2. Penetrant is applied to the surface.

3. Excess penetrant is removed.

4. Developer is applied, rendering the crack visible. (1)

Bulk volume methods range from the simple tap test to ultrasonic screening to the most sophisticated X-ray and computer tomography techniques. The choice of the method depends greatly on the type of defect that is to be detected and criticality of cycle time and production costs. Simple surface defects, core crush in sandwich structures may easily be detected using visual techniques, while tap tests can be used very effectively to determine delaminations or large internal voids. In a tap test the component is tapped lightly with a hard object such as a coin or ring which emits a very dull sound if a delimitation lies beneath the testing point. On the other hand the exact location and size of a delimitation, possible contaminations, voids or micro-porosities can only be detected with ultra-sonic or C.T. techniques. In this respect ultra-sonic scanning has developed to be the most widely-used NDT technique in the aerospace industry due to its high detection fidelity, compactness and relative low-cost compared to C.T. techniques. In ultra-sonic scanning ultrasound is projected into a component and by measuring the strength and time delay of the echo it is possible to detect inclusions (air, solid objects etc.) that differ from the host composite material.

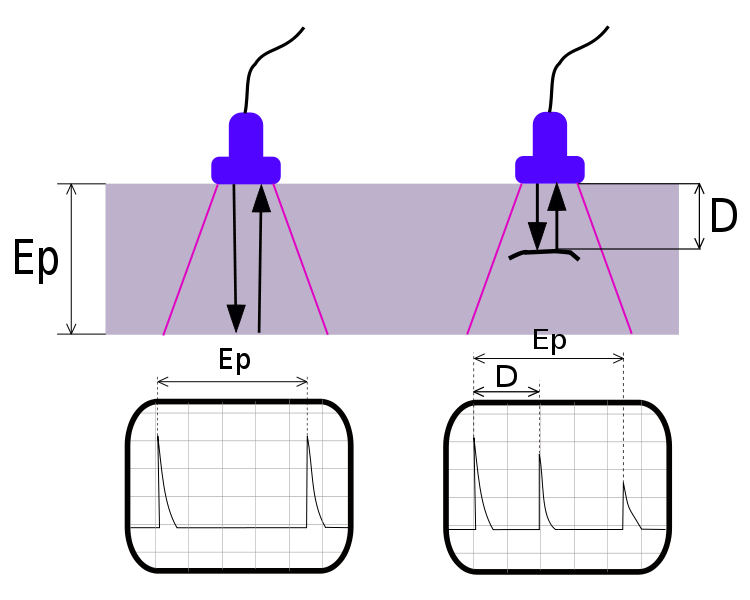

Fig. 3. Principle of ultrasonic testing. LEFT: A probe sends a sound wave into a test material. There are two indications, one from the initial pulse of the probe, and the second due to the back wall echo. RIGHT: A defect creates a third indication and simultaneously reduces the amplitude of the back wall indication. (2)

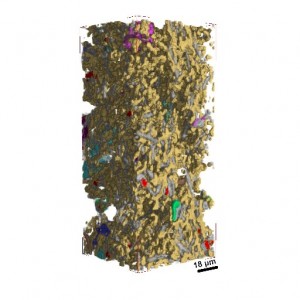

One of the drawbacks of ultrasonic scanning is that some sort of coupling agent (typically water or a gel) is required between the probe and surface of the part to guarantee a high-quality reading. Furthermore, the scanning of large areas can be very time intensive even with the use of multi-probe ultrasonic arrays that can be rolled across a surface or controlled by a robotic arm, such that this technique is typically restricted to critical or highly-stressed components. Finally, CT techniques are currently only widely used in academia where they can give very useful insight into the exact 3D morphology of a cured part and show how and where cracks are initiated and when they propagate. Some pieces of equipment like Synchrotron radiation computed tomography at the University of Southampton can produce extremely detailed 3D plots and videos of parts under load that are very useful to help researchers understand what drives failure in composite materials.

Finally, in recent years global methods such as structural health monitoring have been a hot research topic. In structural health monitoring sensors such as strain gauges or fibre-bragg grating systems are embedded within the structure and provide real time data on the stress state. In this manner the health of the structure can be monitored in real time and service intervals and replacement parts be installed at the required times. However, these systems can probably not be embedded throughout an entire aircraft and require an incredible amount of storage to cope with the continual data stream.

Understanding the detrimental effects of imperfections and the damage mechanisms is essential in order to take full advantage of the benefits that high performance composites have to offer. In this respect non-destructive testing is a very valuable tool for investigating and mapping the internal condition of a component. One of the challenges facing the aerospace and automobile industries in the future is deciding what detail of non-destructive testing is required to guarantee the structural integrity of the products to a high degree of probability during the entirety of its service life and balancing this against the cost that the specific techniques incur.

Image Credit and Sources

(1) Wikipedia, http://en.wikipedia.org/wiki/File:Ressuage_principe_2.svg

(2) Wikipedia, http://en.wikipedia.org/wiki/File:UT_principe.svg

(3) Institute of Materials Science and Technology – Vienna University of Technology, http://mmc-assess.tuwien.ac.at/mmc/?mid_detail=99

Composite Materials and Renewables: Wind Energy

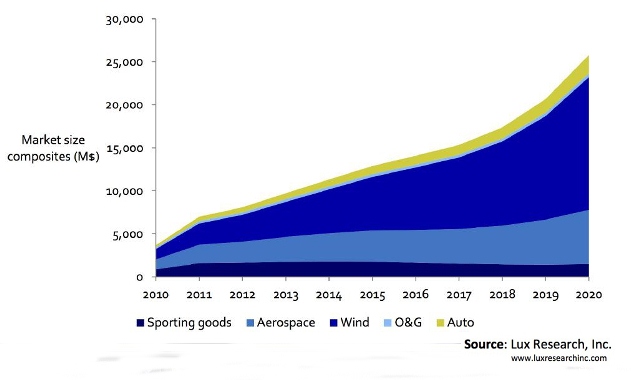

In the aerospace industry the benefits of exploiting the excellent specific strength and stiffness properties of composites in terms of lightweight structural design are immediately apparent. Other advantages of fibre reinforced plastics, such as the relative ease to manufacture complex shapes, and their excellent fatigue and corrosion resistance, have made FRP composites increasingly attractive in the renewable energy sector. Considering the predicted growth of production in wind turbines, accounting for nearly 60% of the entire advanced composites market by 2020 [1], a wide variety of scientific material has been published in recent years regarding the optimisation of advanced composites usage in wind turbines. Furthermore, considerable “blue-sky” research is being conducted that aims to take advantage of the multifunctional capabilities of advanced composites in order to extend their integration in less obvious applications such as tidal turbines and solar panels. The objective of this post is to give a general overview of the novel research conducted to facilitate these new technologies, while giving a more detailed insight into the challenges that engineers face in designing the new generation of 100m wind turbine blades.

Overview

In the last 25-30 years the use of wind turbines for electricity generation has grown from a grass-root “green” initiative to a financially sustainable

primary energy resource [2]. The increasing maturity of the industry can be traced from the small 100-150 kW turbines constructed throughout the 1980s to the large 2-5 MW projects installed both on- and offshore today. This growth can largely be attributed to innovations in the integration of lightweight fibre-reinforced plastics (FRPs), which have facilitated increasingly larger blade lengths as shown in Figure 1. Fibre-reinforced plastics represent a prime material choice for wind turbine blades in terms of structural efficiency since the high specific stiffness limits tip deflections, reduces gravity-induced loading and decreases rotor inertia. Furthermore, the excellent fatigue resistance of FRPs helps to minimise material degradation and maintenance costs over the 20-year design lifespan [4]. A few of the currently largest wind turbines including their blade materials are summarised in Table 1.Table 1: Summary of various Megawatt wind turbines with defining characteristics and blade material choices [5] – [9].

|

Company |

Model |

Blade Length (m) |

Rotor ø (m) |

Power (MW) |

Blade Materials |

|

Vestas |

V120-3MW |

54.65 |

NA |

3 |

glassfiber/carbon spars with glassfiber airfoil shells |

|

Enercon |

E-126 |

NA |

127 |

7.5 |

glassfiber/epoxy with steel mesh for lightning strike |

|

Siemens |

SWT-3.6-120 |

58.5 |

120 |

3.6 |

glassfiber/epoxy composite |

|

Gamesa |

G136-4.5 MW |

66.5 |

136 |

4.5 |

Organic matrix composite reinforced with fiber glass or carbon fiber |

|

Suzlon |

S88-2.1MW |

NA |

88 |

2.1 |

glassfiber/epoxy composite |

However, as governmental subsidies run out the long-term growth of wind technology depends on increasing the energy capture efficiency and therefore turbine sizes. This will require further innovation in lightweight structural design by means of multi-functional and stronger materials, as well as cost-effective manufacturing and installation. A current base model wind turbine section is shown in Figure 2.

The Challenge of Designing a 100m Blade

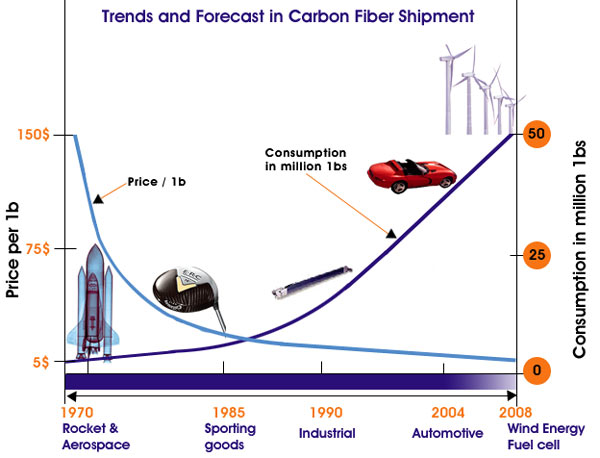

Glassfibre reinforced plastics (GFRPs) were selected in the early wind turbine days because of good material availability and well-documented processing technology. The weight of a turbine blade can statistically been shown to increase with the cubic of the length as shown in Figure 3, resulting in a gravity-induced bending moment that varies with the fourth power of the blade length. To improve on this exponential trend carbon fibre reinforced plastics (CFRPs) are now replacing GFRPs in large turbine blades due to their superior specific stiffness and strength properties. To date a hybrid CFRP-spar/GFRP-skin design is the most widely established solution (Table 1), since this presents the best compromise between improved performance and the higher cost of carbon fibre [11].

Currently the design of wind turbine blades is based around placing unidirectional fibres along the spar axis to provide bending stiffness, while ±45° layers in the skins and webs are used to resist twisting and shearing [12]. Sandia National Laboratories performed a trade-off study concerning innovations in materials and manufacturing processes to ascertain an improved, cost-effective blade design for the next multi-megawatt turbine generation [11]. The researchers conducted finite-element analyses of a baseline fully E-glass/epoxy blade under extreme gust conditions, which showed that the increasing gravity-induced bending loads called for structural reinforcement at the blade root if the blade length was to be scaled up to 60m. Rather than reinforcing the existing design with more E-Glass, replacing the outer half of the spar cap (50% span) with a stitched CFRP laminate was found to result in 32% and 16% reductions in total blade mass and manufacturing cost respectively. The researchers based their decision of the span-wise extent of replacing GFRP with CFRP on a parametric assessment aimed at finding the best compromise in terms of manufacturing cost and increased structural rigidity.

In the future full-span CFRP spars will lead to further reductions in weight and tip deflection with a direct effect on the rotational inertia, aerodynamic performance and energy capture efficiency of the blade. Furthermore, it is estimated that full GFRP rotor blades of 120m in diameter will require 2.5 tons of resin [3] such that through-thickness dissipation of exothermic heat at the thick root sections during cure will become increasingly problematic. In terms of cost, it is currently unclear if the increased demand in carbon fibre by the aerospace, energy and automotive sectors will drive prices up or lead to economies of scale that will further reduce CFRP costs [11]. In the future carbon nanofibre-GFRP hybrid materials may be potential candidates for use in future turbine blades as they combine high strengthening and stiffening potential of carbon nanofibres with relatively cheaper GFRP [13]. The use of carbon fibre for wind turbine blades is further discussed in [14] – [16].

Manufacturing of Turbine Blades

Wet hand lay-up in open moulds has naturally developed as the traditional manufacturing technique for GFRP wind rotor blades due to its process maturity and cost-effectiveness compared to other techniques [2]. In 2008 a survey of wind turbine operators revealed that 7% of all wind turbines blades have to be replaced as a result of failure induced by manufacturing defects [17]. Furthermore, with the expected doubling of production volume in the next 5 years [1], there has been a natural drive towards faster yet more consistent manufacturing processes that facilitate superior material properties. Toward this end pre-preg technology and vacuum-assisted resin transfer moulding (VARTM) have emerged to be promising replacement techniques [11].

VARTM is currently the industrial norm since combining and curing the resin and fibres in one step significantly lowers manufacturing costs. Nevertheless, two of the largest manufacturers in the world, VESTAS and GAMESA, use pre-preg technology to guarantee more repeatable material properties, higher fibre-volume fractions and reduce the degree of fibre-waviness [17]. The main reductions in cost of the VARTM process can be attributed to the use of thicker ply lamina and the elimination of high-temperature and pressure autoclave curing [11]. However, the use of thicker plies exacerbates the magnitude of ply drops in a tapered blade and increases the likelihood of hidden flaws, which may result in the development of delaminations and a shorter fatigue life compared to pre-preg laminates [19] – [20]. Quite recently VARTM has been proven to lend itself to process automation with a subsequent scope for further reductions in cost, and improvement in the aforementioned mechanical shortcomings. MAG Industrial Automation Systems have developed the Rapid Material Placement System (RPMPS), which is an automated blade moulding facility that is capable of laying-up glass and carbon fibre on moulds, cutting the manufacturing time of a 45m blade by 85% [21]. Grande (2008) outlines the Siemens’ innovative IntegralBlade technology that makes blades in one piece, unlike the typical blade that is made in two shells and glued together [22]. The process is based on vacuum infusion with a closed outer mould and an expanding, flexible inner bladder. The IntegralBlade system reportedly offers several advantages, including shorter cycles and more efficient use of manpower and space. Additionally, there are no tolerance issues between the shells and structural spars. Most importantly the blade is an integral structure with no glued joints that could weaken and potentially expose the structure to cracking, water entry, and lightning strikes.

It is clear that both pre-preg technology and VARTM have merits in terms of their application to large turbine blades but the myriad of design factors and possible volatility of material costs currently prohibits the definition of an optimum solution. To guarantee the financial sustainability of wind power the evolution of current manufacturing technology should be of paramount importance, and automated systems such as RPMPS point in the right direction.

Offshore Wind Turbines

As the power of wind turbines has grown and the blade sizes have increased, there has been an increasing amount of wind turbines installed in

offshore locations; this presents a number of problems in supporting the turbine. In shallow waters up to about 30m in depth, the turbine can be supported with a monopole. Beyond this depth, the monopole must have some other supporting members and beyond 50m the turbine needs to be on a floating platform with cabled supports into the seabed [25]. Floating a wind turbine presents unique challenges as the platform must resist the motion of the sea and minimise pitch, roll and yaw whilst still maintaining the weight of the turbine. However, the wind industry has not converged on a standard design and more research is needed to fully overcome the challenge. Floating wind turbines open the possibility for combining wind and tidal power in one construction site and therefore increase the energy captured per installed structure. This hybrid design may be a solution to offsetting the high initial capital costs of renewable energy systems.

Future Developments – Thermoplastics and Morphing

Recently there has been a drive towards using thermoplastic resins in wind turbines in order to take advantage of their higher toughness, faster curing times, unlimited shelf life and the potential for recycling. Although BASF have developed a new acrylonitrile styrene acrylate (ASA) polymer for wind turbine use, the inferior fatigue resistance and high moisture absorption restricts the matrix to being used in small-scale GFRP turbines [27]. However, in the light of the forecasted increase in demand of wind turbines Andersen et al. (2007) make the prediction that by 2040, 380 000 tonnes of FRP will have to be disposed of annually [28]. As around 60% of the scrap created during the incineration of FRP is inorganic ash, and only 30% of FRP waste is currently being recycled, further research into overcoming the structural shortcomings of thermoplastics is essential for a truly eco-friendly use of advanced composite in wind technology. Furthermore, research at TU Delft suggests that the ability to fusion-bond thermoplastics may make it cost-effective to redesign turbine blades with more internal stiffening elements that ultimately facilitate a lighter design solution [29].

In the future the anisotropic behaviour of non-symmetric laminates may be exploited by forcing blades to twist under strong gusts; thereby reducing fatigue loading and allowing the design of longer blades [20]. To improve fatigue life Ong et al. (1999) suggested rotating the primary span-wise fibres by off-axis 20°, which lead to the design of the TX-100 prototype developed by Sandia National Laboratories with 45% volume fraction of carbon fibre at 18° off-axis angle in the spar cap, and 13° for the skins [30] – [31]. Although the TX-100 is less stiff than its non-twisting CX-100 counterpart it increased the fatigue life by 150% [20]. Hulskamp et al. (2011) demonstrated another method of reducing fatigue loads using sensors and actuators to control trailing-edge flaps along the span of the blade. A significant load reduction was found with this small-scale experiment, however issues with scale-up and the integration and reliability of the electronics must still be addressed for this technique to have industrial applications [33]. Continuously cambered morphing trailing edge flaps have significant advantages over hinged flaps as they reduce the complexity of the design leading to a lower part count, simpler manufacturing techniques and increased aerodynamic efficiency [34]. Towards this end Daynes & Weaver (2011) have successfully manufactured a prototype of a continuously cambered morphing trailing edge as shown in Figure 6 [32]. The trailing edge produces the same lift characteristics as a traditional hinged flap with 34.4% less flap tip deflection (13.1 degrees to 20 degrees), thereby reducing the required actuator work by 69.2% under maximum aerodynamic pressure loading. The trailing edge flap is manufactured from a NOMEX honeycomb core sandwiched between woven CFRP upper and silicon lower skins, and actuated by a CFRP push-pull linkage as schematically depicted in Figure 9.

Corrosion and erosion of FRP blades are substantial problems for offshore wind turbines. Offshore turbines suffer from increased wind, UV and high salinity with wetting-drying cycles that have been found to increase corrosion. Erosion may also occur in a number of environments due to ice formation on the blades and the impact of sand, earth and insects. An exhaustive review of wear in FRP materials is presented in [35]. Surface coatings have been considered in order to reduce the effects of corrosion and erosion. Non-stick coatings may be used to resist insect-impact and tapes have been applied to the leading edge of blades in order to protect this erosion-prone area [36]. Coating GFRP with electroless Ni-P has also been found to increase resistance to NaCl corrosion [37] and superhydrophobic coating has proved very successful at preventing water and UVC damage, although more work is needed to prevent icing [38]. Lightning protection is also an issue, with taller blades and carbon reinforcements making turbines increasingly attractive to lightning strikes. One suggestion is to use two down conductors instead of one, which protect the turbine by connecting it to the ground [39].

Conclusions

As the demand for renewable wind energy will continue to increase in the coming years there is a real incentive to build considerably larger wind turbines in order to improve the overall energy capture efficiency. Carbon fibre reinforced plastics will play an essential role in facilitating longer turbine blades but certain reluctance prevails in the industry regarding the higher material costs compared to glass fibre reinforced plastics. For this reason, improvements in component quality produced by out-of-autoclave processes such as VARTM and the development of cost-effective pre-preg materials is of paramount importance. Another promising alternative to reducing blade weight and manufacturing cost is the integration of multifunctional composites, where embedded technologies such as SHM or self-healing will enable the reduction of safety factors and therefore decrease material usage. As the use of advanced composites continues to grow a major research effort will have to focus on developing new resin systems that lend themselves to ecological recycling.

References

[1] Red, C. (01. 06 2008). Composites World. Viewed on 05. 11 2011 from Wind turbine blades: Big and getting bigger: http://www.compositesworld.com/articles/wind-turbine-blades-big-and-getting-bigger

[2] Brøndsted, P., Lilholt, H., & Lystrup, A. (2005). Composite Materials for Wind Power Turbine Blades. Annu. Rev. Mater. Res. , 35, 505-538.

[3] Rahatekar, S. (2011). Expoxy Resins – Polymers and Polymer Composites. Bristol, UK: ACCIS University of Bristol.

[4] Holloway, L. (2010). A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties . Construction and Building Materials , 24, 2419-2445.

[5] Vestas Wind Systems A/S. Vestas. Viewed on 04. 12 2011 from Download brochures: http://www.vestas.com/en/media/brochures.aspx

[6] Enercon GmbH. Enercon. Viewed on 04. 12 2011 from E126 State of the Art: http://www.enercon.de/en-en/66.htm

[7] Siemens AG. Siemens Energy. Viewed on 04. 12 2011 from Siemens Wind Turbine SWT-3.6-120: http://www.energy.siemens.com/us/en/power-generation/renewables/wind-power/wind-turbines/swt-3-6-120.htm#content=Technical%20Specification

[8] Gamesa Corporación Tecnológica. Gamesa Corporation. Viewed on 04. 12 2011 from Wind Turbines: http://www.gamesacorp.com/en/products-and-services/wind-turbines/productos-y-servicios-aerogeneradores-2catalo.html

[9] Suzlon Energy. Suzlon – Power a Greener Tomorrow. Viewed on 04. 12 2011 from S88-2.1 MW : http://www.suzlon.com/products/l2.aspx?l1=2&l2=9

[10] Hayman, B., Wedel-Heinen, J. and Brondsted, P. (2008) ‘Materials challenges in present and future wind energy’, Mrs Bulletin, 33(4), 343-353.

[11] Griffin, D., & Ashwill, T. (2003). Alternative Composite Materials for Megawatt-Scale Wind Turbine Blades: Design Considerations and Recommended Testing . Journal of Solar Energy Engineering , 125, 515-521.

[12] Dutton, A. et. al. (2010). Novel materials and modelling for large wind turbine blades. Proceedings of the Institution of Mechanical Engineers Part A. 224(A2), S. 203-210. Journal of Power and Energy.

[13] Merugula, L., Khanna, V., & Bakshi, B. (2010). Comparative Life Cycle Assessment: Reinforcing Wind Turbine Blades with Carbon Nanofibres. Proceedings of the 2010 IEEE International Symposium on Sustainable Systems and Technology. Los Alamitos: IEEE Computer SOC.

[14] Berry, D. (2007). Design of 9-Meter Carbon-Fibreglass Prototype Blades: CX-100 and TX-100. Warren: TPI Composites, Inc.

[15] Dayton, A., & Griffin, T. (2003). Alternative Composite Materials for Megawatt-Scale Wind Turbine Blades: Design Considerations and Recommended Testing. Journal of Solar Engineering , 125 (4).

[16] Locke, T. (2006). Fabrication, Testing and Analysis of Anisotropic Carbon/Glass Hybrid Composites Volume 1: Technical Report. Alberquerque: Sandia National Laboratories.

[17] Cairns, D., Nelson, J., & Riddle, T. (2011). Wind Turbine Composite Blade Manufacturing: The Need for Understanding Defect Origins, Prevalence, Implications and Reliability . Montana State University , Department of Mechanical and Industrial Engineering. Albuquerque, NM: Sandia Corporation.

[18] Siemens AG. Siemens Energy. Viewed on 04. 12 2011 from Rotor Blades for Wind Power Stations: http://www.siemens.com/press/en/presspicture/?press=/en/presspicture/pictures-photonews/2008/pn200801.php

[19] Hallett, S., & Harper, P. (2011). A Numerical Fatigue Model for Application to Tidal Turbines. Submitted.

[20] Ashwill, T. (2009). Materials and Innovations for Large Blade Structures: Research Opportunities in Wind Energy Technology . 50th AIAA Structures, Structural Dynamics, & Materials Conference. Palm Springs, CA: American Institute of Aeronautics and Astronautics.

[21] Dvorak, P. (01. 06 2009). Lay-up equipment cuts 85% off time to manufacturer big blades . Abgerufen am 28. 10 2011 von Windpower Engineering: http://www.windpowerengineering.com/design/mechanical/blades/lay-up-equipment-cuts-85-off-time-to-manufacturer-big-blades/

[22] Grande, J. (10 2008). Wind Power Blades Energize Composites Manufacturing. Plastics Technology .

[23] Polyzois, D., Raftoyiannis, I., & Ungkurapinan, N. (2009). Static and dynamic characteristics of multi-cell jointet GFRP wind turbine towers. Composite Structures , 90 (1), 34-43.

[24] Gutiérrez, E., & al., e. (2003). A Wind Turbine Tower Design Based on the Use of Fibre-Reinforced Composites. European Comission Joint Research Center.

[25] Chen, L., Ponta, F., & Lago, L. (2011). Perspectives on innovative concepts in wind-power generation. Energy for Sustainable Development.

[26] S. Butterfield, W.M., J. Jonkman and P. Sclavounos {2005). Engineering Challenges for Floating Offshore Wind Turbines. Offshore Wind Conference. Copenhagen.

[27] Stewart, R. (02. 05 2011). Reinforced Plastics. Viewed on 29. 10 2011 from Thermoplastic composites – recyclability and fast processing top list of benefits.

[28] Andersen, P., Borup, M., & Krogh, T. (2007). Managing long-term environmental aspects of wind turbines: a prospective case study. International Journal of Technology, Policy and Management , 7 (4), 339-354.

[29] Marsh, G. (08. 02 2010). Reinforced Plastics. Viewed on 29. 10 2011 from Could thermoplastics be the answer for utility-scale wind turbine blades: http://www.reinforcedplastics.com/view/5825/could-thermoplastics-be-the-answer-for-utilityscale-wind-turbine-blades/

[30] Ong, C., Wang, J., & Tsai, S. (1999). Design, Manufacture and Testing of a Bend-Twist D-Spar. AIAA-1999-25 Proceeding ASME/AIAA Wind Energy Symposium. Reno, NV: AIAA.

[31] Liu, W., & Zhang, Y. (2011). Bend-Twist Coupling Design and Evaluation of Spar Cap of Wind Turbine Compliance Blade. Manufacturing Engineering and Automation I , Pts 1-3, 1400-1405.

[32] Daynes, S., & Weaver, P. (2011). A Morphing Wind Turbine Blade Control Surface. Proceedings of the ASME 2011 Conference on Smart Materials, Adaptive Structures and Intelligent Systems. Phoenix, AZ: ASME.

[33] Hulskamp, A., & al., e. (2011). Design of a sclaed wind turbine with smart rotor for dynamic load control experiments. Wind Energy , 14 (3), 339-354.

[34] Daynes, S., Hall, S., Weaver, P., Potter, K., Margaris, P., & Mellor, P. (2010). Bistable Composite Flap for an Airfoil . Journal of Aircraft , 47 (1), 334-338.

[35] Patnaik, A., & al., e. (2010). Solid particle erosion wear characteristics of fiber and particulate filled polymer composites: A review. Wear , 268, 249-263.

[36] Dalili, N., Edrisy, A., & Carriveau, R. (2009). A review of surface engineering issues critical to wind turbine performance. Renewable & Sustainable Energy Reviews , 13 (2), 428-438.

[37] Lee, C. (2008). Corrosion and wear-corrosion resistance properties of electroless Ni-P coatings on GFRP composite in wind turbine blades. Surface & Coatings Technology , 202 (19), 4868-4874.

[38] Karmouch, R., & Ross, G. (2010). Superhydrophobic wind turbine blade surfaces obtained by a simple deposition of silica nanoparticles embedded in epoxy. Applied Surface Science , 257 (3), 665-669.

[39] Rachidi, F., & al., e. (2008). A review of current issues in lightning protection of new generation wind-turbine blades. IEEE Transactions on Industrial Electronics , 55 (6), 2489-2496.

Developments in Composite Materials

I have just returned from the International Conference for Composite Materials (ICCM) in Montreal, Canada and would like to share a few observations and key points about the developments in the composite world that may not be so easily accessible to a broader audience.

1) The Great Advance – Applications

ICCM is the biggest conference for composite materials and this year united over 1500 delegates from academia and different industrial representatives from the classical sectors aerospace, wind energy and high performance cars to newer sectors such as mass market cars (e.g. BMW i3), biomedical applications and even musical instruments. The motto of the conference “Composite Materials: The Great Advance” aptly captures the current state of technology in the industry. Since the 1960 considerable amount of research has been conducted to elucidate the mechanical and chemical properties of the fibre material, matrix and cured composite under various conditions such that the global behaviour of these materials is now sufficiently characterised. This maturity in technology coupled with the ever decreasing costs and the inherent benefits of high specific stiffness and strength that fibre-reinforced plastics have to offer, has led to the increasing application of composite materials in very different industries that we see today. Thus the “great advance” of composite materials towards wide-spread use in many industrial sectors.

2) The Great Advance – Novel Technologies

Furthermore, “The Great Advance” also relates to novel composite materials with much greater complexity that blur the lines between what is a material and what is a structure. Of course on a macroscopic scale one could say the steel in a steel bridge is the “material” that has been used to construct the “structure” that is the bridge. Therefore in this classical interpretation steel is just the building block to make the bridge, while the structure itself is the final product that performs a function. However on a microscopic scale we could argue that steel is a structure in itself since it is “constructed” of different sized grains that contain different metallic compounds and is thus an arrangement of small particles i.e. a microstructure. We could of course continue this argument further and further up to the atomic scale at which point we have reached the field of nanotechnology. This field of research has enjoyed much popularity in recent years since by manufacturing our products from the ground-up, i.e. from the nanoscale to the macroscale, we can control the properties of our product at multiple length-scales and therefore tailor the characteristics to be optimal for the desired function in service or even add some sort of multi-functionality to the structure/material. Since the material and structure are built at the same time the dividing line that used to distinguish between these two concepts is blurred. Even for a simple composite laminate comprised of a stack of individual layers this divide is no longer so clear since we can define the properties of each ply in the stacking direction and therefore have control over one more length scale.

Therefore in the future there will be a great advance towards novel and multifunctional materials/structures that perform so much more than carrying structural loads. Currently the design of composite structures is still in some cases dominated by a “black aluminium” approach. That is taking the current designs that have worked so well over the last decades using aluminium and replacing them by an equivalent composite design. The problem with this is that on one hand the composite material may not be suitable to carry loads in the same configuration e.g. loads through the thickness have to be avoided to prevent delaminations. Most importantly however, such a design approach hinders the greatest advantage of this new material system, which is to facilitate entirely new structures in terms of functionality and shape that arise as a results of their inherent properties. Only by completely re-designing structures from the ground-up and taking the intricacies of this new material system into consideration can we arrive a new optimal solutions or conversely ascertain that a metal solution actually works better under some circumstances. In the following I want to share a few exciting technologies that you may see in the near future.

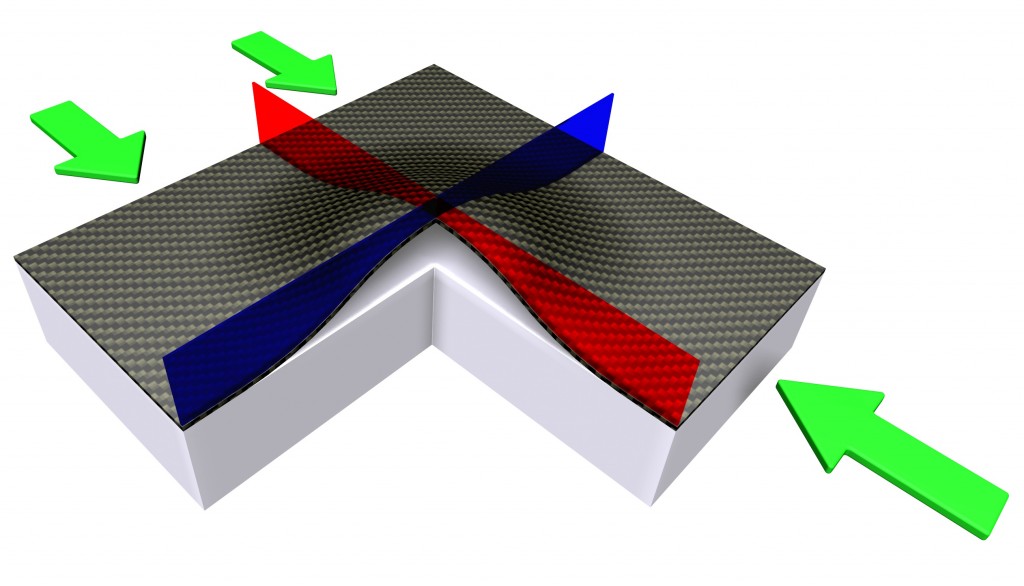

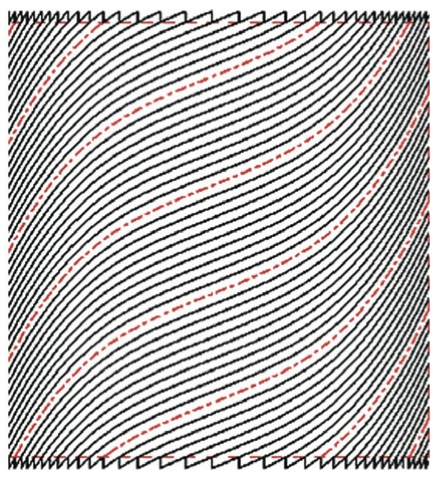

1) Variable stiffness technology

This is my field of research and essentially what we are currently doing is changing the fibre direction over the planform of the plate such that we have curvilinear fibres rather than the straight fibre laminates that we use today. In many aerospace applications we require different laminate stacking sequences in different parts of the structure. Abruptly changing from one stacking sequence to another can lead to stress concentrations and thus structurally weaker areas at the interface. Using the variable fibre concept we can easily spatially blend from one layup to another to reduce these problems. Furthermore, we can arrange the fibre paths to follow the dominant load paths as for example around a window in an aircraft fuselage. Loads in a structure always follow the path of highest stiffness. So by aligning the fibres in the load direction in supported areas of the laminate (for example the vertical edges in Fig. 3 below if the load is applied vertically onto the horizontal edges), a large portion of the stress can be removed from the unsupported centre of the panel, which can greatly improve the elastic stability of the structure. This has great potential for future wing structures since the design of wing skins is greatly governed by local buckling (Fig. 4). It has been shown that the buckling loads can be improved by 70%-100% using variable stiffness technology (5), thus the possibility exists to reduce the weight of wing structures by up to 20% using this technology.

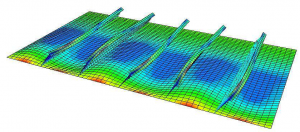

Fig. 4. Buckling analysis of a stiffened wing panel. The stiffeners break the buckling mode shapes into smaller wavelengths that require higher energy to form than a single wave (4)

Another form of various stiffness technology is placing material in areas where it is needed and removing it from areas where it is not required. Nature is an expert in achieving this and many of our current design are based on bio-mimicry. For example, your bones are continuously being re-modelled based on the stresses that are placed on your skeleton. In this way the density of your bones is increased in highly-stresses areas and decreased in areas that are not used so much. In the same way sea-sponge arranges its structure in a way to achieve the most efficient design. Similarly, wood possesses an incredibly complex microstructure that is composed of different structural hierarchies at different length scales. This is similar to a rope where individual fibres are twisted together to make strands, strands are twisted together to make bundles, and bundles twisted together to make the complete rope. This approach of designing at multiple length-scales makes wood very ductile and resilient to cracks. In this manner attempts have been made to reproduce such a hierarchical design by arranging short fibres using standing ultrasonic waves.

Fig. 5. Microstructure of wood. Notice the different structures at different length scales that gives wood its inherent strength (6).

2) Self Healing

Yes, materials can heal themselves. The most popular example is that of self-healing asphalt, which was presented a few years ago at a TED conference. In terms of composites 100% recuperation of mechanical properties have been achieved when the mode of failure has been dominated by matrix cracks. In high performance composites the matrix is currently some sort of thermoset or thermoplastic, which allows vascules of uncured resin to be included in the structure which may break open as a crack propagates. The uncured resin then permeates through the open crack and cures in-situ to repair the full functionality of the part. The dissemination of the healing process can also be achieved using very thin vascules that are arranged throughout the part. In this manner the structure starts to behave very much like a living organisms with the vascules serving as pathways for repair very similar to the veins in an organism. Recently a great article by the BBC summarised the major achievements in this field.

3) Nanotechnology

Nanotechnology has been extremely popular during the last 20 years due to the fact that theoretical predictions promise incredible benefits for almost all applications in engineering. In terms of advanced composites however, there are still problems of evenly dispersing nanotubes in resins with agglomeration or alternatively producing continuous nano-strands at low costs. In the aerospace industry they show great promise in increasing the electrical conductivity of laminates to improve their resistance against lightning-strike, creating structures for magnetic shielding and providing interlaminar strengthening using nano-forests. One of the cooler things I saw at ICCM was research conducted on nano-muscles, which are essentially nano-fibres that have been twisted into a rope and can achieve very high actuation forces and strokes at very little mass.

4) Structural Batteries / Energy Harvesting

Solar power has incredible potential as an energy source since it is the largest form of energy available for consumption on earth and is limitless. However, solar power is sporadically dependent on the weather conditions, which makes energy conversion rather cost intensive and inefficient. However, solar energy harvesting might find increasing use if actively integrated into load-bearing components as a multi-functional structure. Bonding thin-film solar cells onto lightweight composites would eliminate the material redundancy of stand-alone supporting structures and could easily be integrated into current laminate manufacturing technology. Photovoltaic (PV) cells have been imbedded in composite laminates and their performance has not been impeded by the curing process. However, the performance of the PV cells diminishes rapidly under static loading since the loading causes cracks in the cells. Similarly there are ideas to create structural batteries such that the load carrying chassis of a car can be “charged-up” to additionally serve as the battery for an electric powertrain. Of course this would have the great advantage that the heavy batteries used today could be eliminated to some extent. BAE systems are working on technology to embed battery chemistries into the carbon fibre fabric.

5) Morphing

Finally, morphing or shape-changing structures have been extensively studied since the 1970’s for providing aircraft with the possibility of adapting the shape of their wings to provide the optimal lift for different flight scenarios. Of course this is to some extent already used in aircraft with the aid of leading edge slats and trailing-edge flaps to increase the lift-coefficient for slower flight regimes such as landing and lift-off and in Formula 1 using drag reduction system of the rear wing. However, slats and flaps on an aircraft greatly increase the drag of the profile during deployment and increase the weight of the structure do the heavy actuation mechanism. Therefore the aim is to design an integral system such as the trailing-edge design shown below. Other examples of morphing structures include air intakes for cars, noise-reducing chevrons on jet-engines, or high-temperature composites used for jet-engine turbine blades that change there angle of attack based on the temperature of the airflow around them.

However, in most cases these technologies are very difficult to apply to primary aircraft structures. This is because there is a direct conflict between the high-stiffness, high-strength requirement for carrying loads and the low-stiffness, large-deflections required for shape-changes. Thus, a driver to facilitate these technologies will be the development of materials that change there mechanical properties under different circumstances.

3) The Great Advance – Solving “big” problems for larger scale implementation

Finally, one of themes during the conference was trying to solve some of the major problems faced by the industry hindering further implementation of current composite technology in all industrial sectors. Of course for some industries such as mass consumer automobiles the biggest barrier to entry is cost. The new BMW i3, which will enter the marketplace at the start of 2014, will cost £30,000+ and is therefore quite a big investment for a small city vehicle. Of course some of the cost can be attributed to the cost of the electrical drivetrain and batteries but other manufacturers such as Renault have shown that a lot of these costs can be reduced by employing a scheme based on renting batteries rather than buying them with the vehicle. In case of the i3 a lot of the extra cost is simply down to the fact that BMW are the first to build a mass produced automobile using a large amount of fibre-reinforced plastics in primary structural parts. Not only is cost of raw material much higher than for lightweight metals such as aluminium but the manufacturing processes and supply chain management required for reliable mass production were simply not in-place beforehand. Furthermore, a shift in design methodologies is required since the chemical and mechanical behaviour of composites is so different from the metal environment that the automobile industry is so used to dealing with. As an example, proving the structural integrity for the incredible rigorous crash/impact certification using rather brittle composite materials compared to more ductile metals is a challenge in itself. Thus, the relatively high price-tag of the i3 incorporates some of the research and development costs that BMW have had to face in developing composite technology for their market sector. No doubt the cost of mass market composite cars will reduce drastically in the next decade as the raw material price further reduces and design methodologies and manufacturing processes mature.

Another major issue hindering the implementation of composites especially in the aerospace industry is the difficulty of predicting the failure behaviour of these materials. On problem is the large number of failure modes that may occur: fibre breakage, matrix cracks, delamination, fibre crimping, fibre-matrix debonding, global and local buckling etc. and thus finding accurate failure loads for all these phenomena under different load cases. Since a larger number of these failure mechanisms originate on a local, micro-mechanical scale high-fidelity 3D Finite Element models are often needed to fully understand the mechanisms of failure and predict the load-carrying capability of different structures. Considering the size of any commercial aircraft it is absolutely inconceivable to apply such detailed and computationally expensive analysis tools to every part of an aircraft. Furthermore, the failure mechanisms are not as well defined as for metal materials. That is in classical tensile or compressive tests a specimen may undergo some form of non-linearity that may for a metal specimen be classified as a failure event but for the composite considerable residual strength is available. Conversely the failure behaviour of composites can be very brittle with very little warning compared to the gradual, ductile failure mechanism of most metals used in the aerospace industry. Considering the intricacies of composite failure modes and the fact that the individual failure modes may interact or even change in criticality depending on the size of the component and environment in which it is used, it is no wonder that currently very conservative safety factors are being employed for primary composite aircraft structures that greatly offset the weight-savings that are possible using this new material system. Thus, one of the biggest if not the biggest topic in composite structural design for the next couple of years will be the challenge of developing simple and yet robust failure criteria to be used for composite designers.

References

(1) http://www.luxresearchinc.com/blog/wp-content/uploads/2011/11/GotW11_27_11.jpg

(2) http://www.lucintel.com/images/market_report_img/marketcarbon_img/CarbonMarket3.jpg

(3) Kim et al. (2012). “Continuous Tow Shearing for Manufacturing Variable Angle Tow Composites”. Composites: Part A, 43, pp. 1347-1356

(4) http://www.dnv.com/binaries/PULS-buckling_tcm4-284864.JPG

(5) Gürdal Z, Tatting B, Wu C. (2008). “Variable stiffness composite panels: Effects of stiffness variation on the in-plane and buckling response”. Composites: Part A, 39(5), pp. 911-922.

(6) Greil P, Lifka T, Kaindl, A. (1998). “Biomorphic Cellular Silicon Carbide Ceramics from Wood: I. Processing and Microstructure”. Journal of European Ceramic Society, 18(14), pp. 1961-1973.

(7) Rincon, P. (2012). “Time to heal: The material that heal themselves.”http://www.bbc.co.uk/news/science-environment-19781862

(8) Daynes S & Weaver P.M. (2011). “A Morphing Wind Turbine Blade Control Surface”. Proceedings of the ASME 2011 Conference on Smart Materials, Adaptive Structures and Intelligent Systems. Phoenix, AZ: ASME.

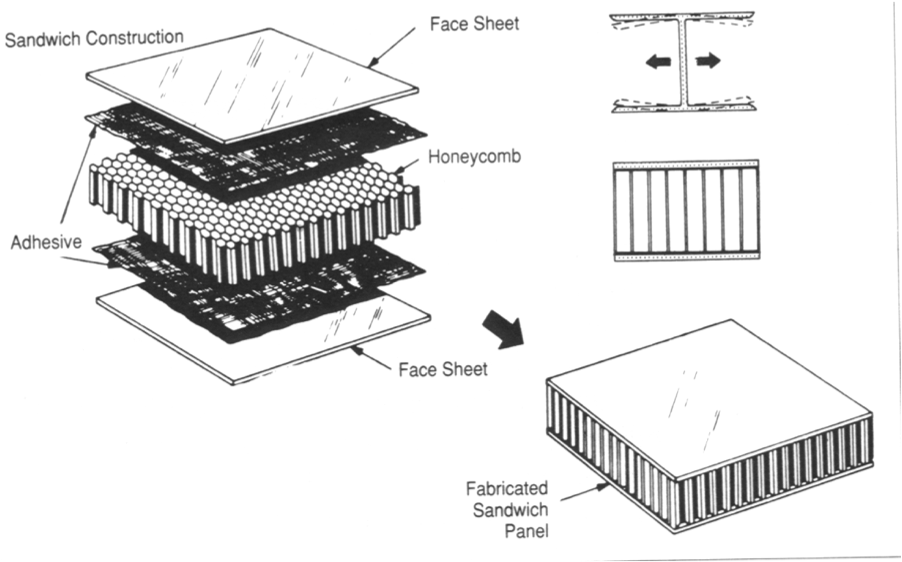

In this post I want to use the sandwich panel as an example to explain some basic concepts about bending of structures. The explanations in this post are kept very basic and are similar to a first semester course in structural mechanics. Sandwich panels are an important composite structure in aerospace applications as well as in high performance automobiles, boats and wind turbines. Typically a sandwich panel is comprised of a low stiffness, low density inner core enclosed by two stiff outer skins, as shown in Figure 1, where the whole assembly is held together by some sort of structural adhesive (Figure 2). The outer skins are typically made from stiff carbon fibre or aerospace grade aluminium.

The inner core is typically a Nomex or metal honeycomb, or an open or closed cell foam. Nomex is an aramid polymer similar to Nylon that is flame-resistant and can be manufactured in paper sheet form. Nomex is a great choice for the interior of aircraft cabins such as the floor panels due to its high safety in the event of fire. Multiple sheets of Nomex paper can be placed on top of each other and glued together at the node locations by lines of adhesive, which are offset spatially between different layers. This large stack of Nomex can then be cut into smaller strips and expanded to form a sheet of Nomex honeycomb. Alternatively closed cell foams such as Rohacell® are commonly used for the core, which are denser then there open cell counterparts but prevent moisture ingress in service and have better mechanical properties.

But what is the advantage of using a sandwich panel?

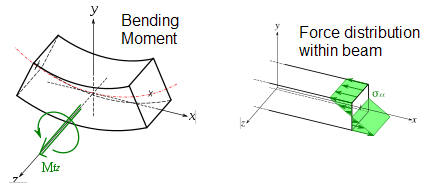

Various structures on an aeroplane are subjected to bending loads. Essentially the bending of a beam or a plate, by say some sort of pressure loading over its surface, is equivalent to grabbing the edges and applying a moment or rotation. Under pure bending Engineer’s bending theory assumes that the structure resists this moment by a linear variation of stress through its thickness. Thus, the maximum stresses occur at the top and bottom surfaces, one being compressive and the other tensile, while the stress at the middle of the beam thickness is zero. This unstressed location is called the neutral axis. For pure bending the neutral axis is always located at the centroid of the cross-section (the mid-plane for a rectangular cross-section) and can be calculated using the integral expression for the first moment of area. Therefore we can see that that the structure balances the externally applied bending moment by an internal force couple of equal magnitude where the fulcrum of the couple is the location of the neutral axis.

However this linear variation of stress is not very efficient since the cross-section of the beam is not uniformly stressed i.e. it would be more efficient if the whole cross-section was constantly loaded by the average stress to spread out the load. One method to improve the design is to cut-out the material close to the neutral axis in order to reduce structural mass as shown in Figure 5. Another possibility is to use a sandwich panel i.e. place stronger material towards the outside where it is needed and replace the interior section with a less dense and therefore lighter (and generally weaker) material to save weight.

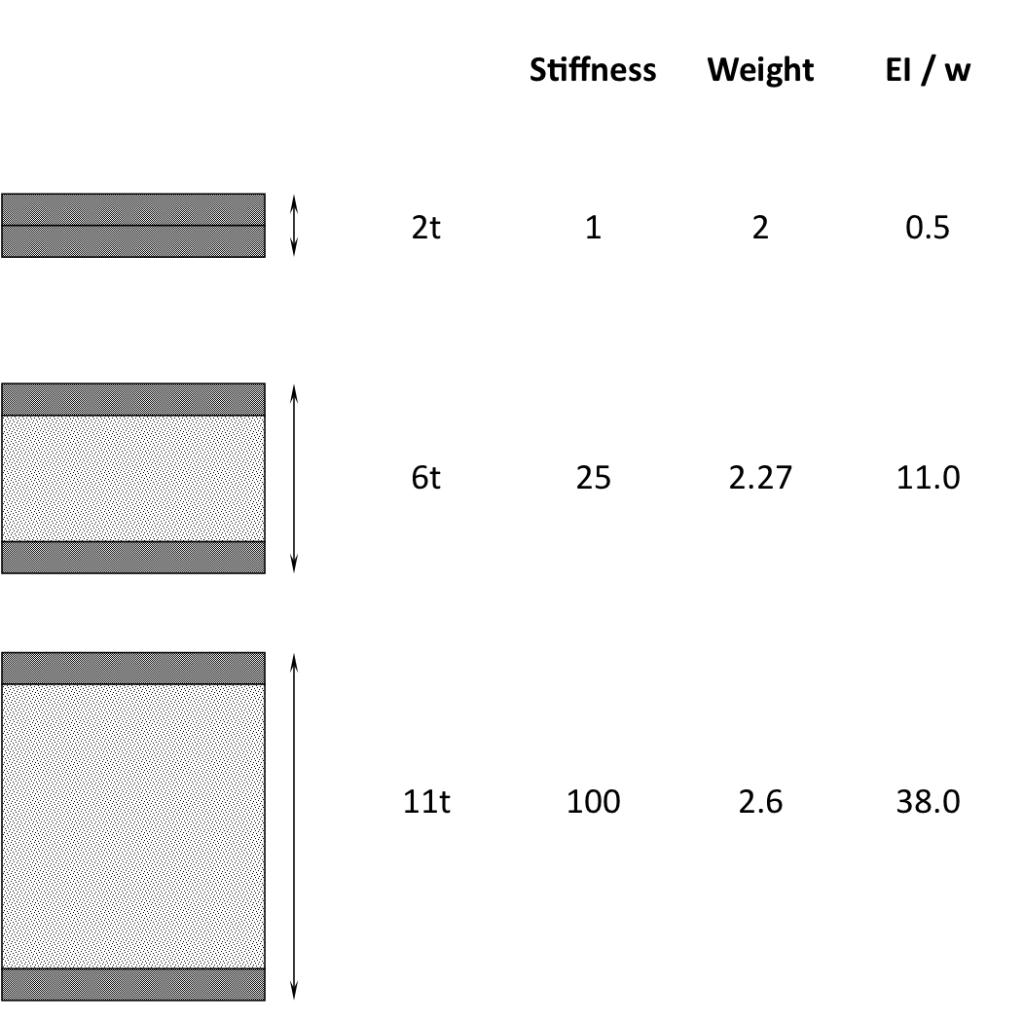

A major advantage of the sandwich construction compared to the flared hole design is that the core separates the stiff outer skins, placing them as far as possible from the neutral axis. The degree in which a structure prevents deflection in bending is known as the bending rigidity EI, where E is the Young’s modulus or stiffness of the material used and I is the second moment of area. The second moment of area I, which is the bending resistance of the cross-section, increases the more mass is located away from the neutral axis. This is analogous to rotational motion where the inertia of rotation increases the further away the rotating mass is located from the centre of rotation. In fact, as the name “second moment of area” suggests, the bending resistance increases with the square of the distance from the neutral axis. Thus a sandwich panel moves two stiff skins (high values of E such as Carbon fibre laminates) far away from the central neutral axis in order to maximise the product EI and therefore create a structure of incredibly high specific flexural stiffness i.e. high bending stiffness coupled with minimum mass. The improvements of stiffness versus weight of a sandwich panel by increasing the separation of the two face sheets is clearly illustrated in Figure 6. Here the density of the face sheets is assumed to be 15 times higher than that of the core.

Apart from increasing the bending rigidity another advantage of using sandwich panels is that it actually concentrates the direct bending stresses (axial and shear

) in the face sheets. This is because when a structure deforms the load always distributes relative to the stiffness of the different parts. For example, when two springs are aligned in parallel and fixed on one end by a support and are displaced by the same extension x on the other end the load taken by spring 1 will be twice as high as that by spring 2 if

.

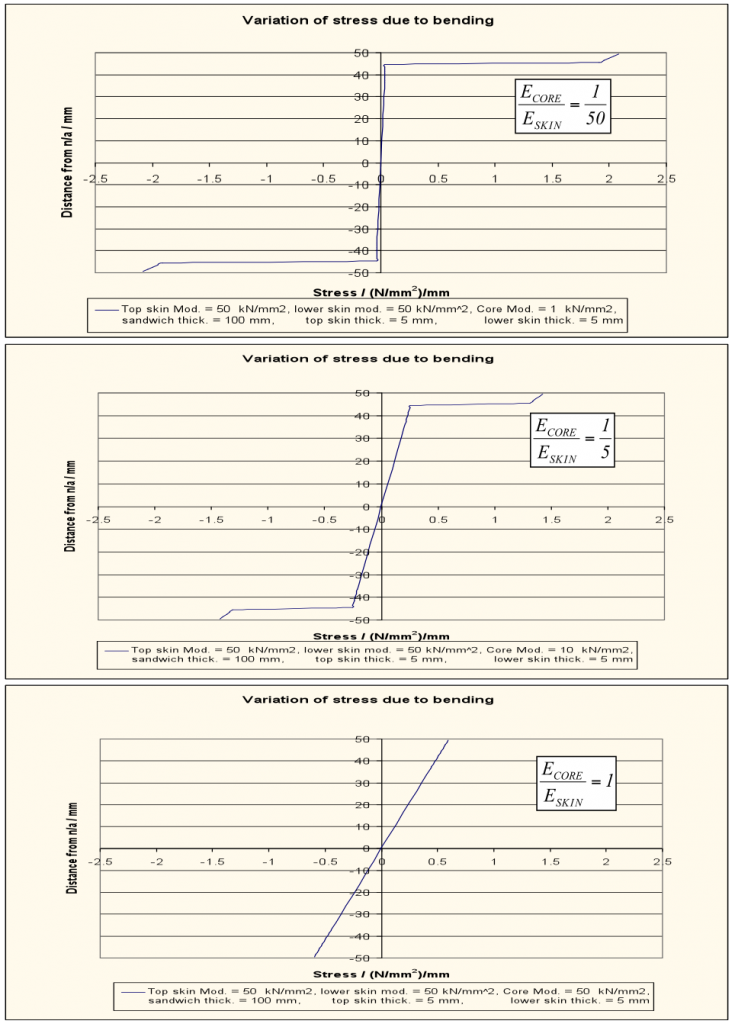

This is equivalent what happens to in a sandwich beam. Since the face sheets have much higher Young’s modulii than the low-density core, in bending the large majority of the direct bending loads is actually taken by the face sheets. This means that the stress distribution is no longer continuously linear through the entire cross-section as for an isotropic material in Figure 4, but actually piecewise linear and discontinuous at the interfaces. For example Figure 8 below clearly indicates how the variation of stress through the thickness of the sandwich panel changes as the stiffness mismatch between the core and face sheets is increased. As the modulus of the skins reaches 50 times that of the core there is a large jump in bending stress from just over zero to about 2 MPa. Compared to the case of equal Young’s modulus this solution is much more efficient since both the skins and the core are more uniformly stressed. The limitation of this design is that the large discontinuity of bending stress at the interface may cause excessive transverse shear stresses at the interface that can literally pull the face skins away from the core and cause de-bonding of the two parts. This is why it is important to use a core with high transverse shear modulus and strength such as honeycomb to absorb these transverse shear loads. Furthermore, the core transverse shear strength is important for resisting point or distributed pressure loadings over the surface of the face sheets and give local support for fasteners.

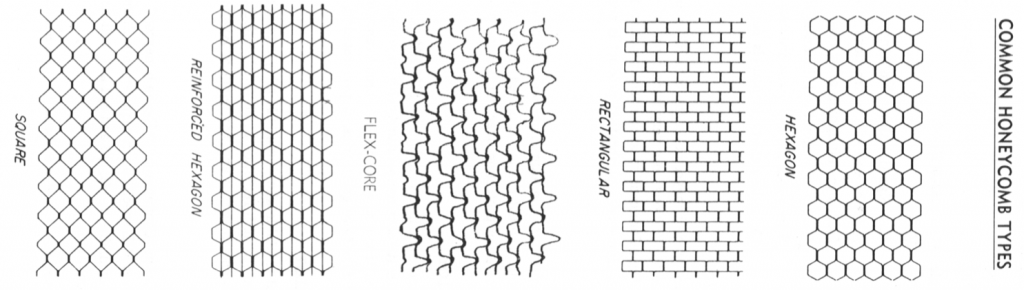

Fig. 8. In-plane stress profile through the thickness of a sandwich panel for various ratios of core-to-face sheet Young’s modulus

Of course there are also many drawbacks of using sandwich panels. For example when using honeycomb cores it is very hard to form complex curved shapes using the standard hexagonal matrix shape. This is because honeycomb has very high values of Poisson’s ratio such that the anti-clastic curvature effects in bending are quite pronounced. This means that when the honeycomb is bent to adhere to a certain shape it will form opposite curvature in the perpendicular direction to form a saddle shape. During in service bending deformation this will also cause the centre of the core to want to pull away from the face sheets again leading to excessive transverse shear and normal stresses at the interface and possible de-bonding of the core and face sheets. In fact de-bonding may also occur due to impact events or slow moisture ingress into the open cell honeycomb structure during service. Furthermore, when not properly designed honeycomb cores may collapse under the external pressure loading when the sandwich panel is cured in the high-temperature and pressure oven known as an Autoclave. Some of these drawbacks can be overcome by using closed-cell forms such as Rohacell®, which have lower degrees of anti-clastic curvature and, being “closed-cell”, greatly reduce the danger of water ingress into the core. The drawback of these foams is that there intrinsic higher density makes them heavier than the equivalent honeycomb solution. Alternatively, different cellular core configurations other than honeycomb such as Flex-core, rectangular and square may be used to reduce the anti-clastic curvature problem.

In metal construction the analogy to the sandwich beam is the I-beam seen in many civil constructions. Here the two flanges are located away from the neutral axis by the vertical web section. The difference in this design is that the vertical web section does also take considerable direct in-plane loads since it is of the same material and therefore stiffness as the two flanges. However, I-beams are much more cost-effective than sandwich beams since they can be easily mass-produced and do not suffer difficulties such as debonding between the face sheets and the core.

In summary a sandwich comprises,

- two stiff and lightweight face sheets that predominantly take in-plane stresses and shear loads

- a low-density core that takes transverse shear loads, separates the face sheets for high bending rigidity, supports the face sheets against buckling modes forming and can give local support for fastener loads

- an adhesive holding the entire assembly together which transfer shear loads to the core and keeps the skins in the correct location.

References

(1) http://img.nauticexpo.com/images_ne/photo-g/sandwich-panel-carbon-fiber-honeycomb-37057-385887.jpg

(2) http://www.paneltech.biz/photos/honeycomb-corrugated.gif

(3) http://www.learneasy.info/MDME/MEMmods/MEM30006A/Bending_Stress/Bending_Stress.html

(4) http://www.williammaloney.com/Aviation/VintageWingsOfCanada/HawkerHurricane/images/37HurricaneFuselageFrame.jpg

(5) http://scienceworld.wolfram.com/physics/simg476.gif

There is a saying that your audience will halve for every equation you put in a piece of writing. Well, in this case I am going to make an exception and go through the detailed derivation of the Breguet Range equation. The reason for doing this is that the maths is not very difficult but the implications of the equation are known to every pilot on earth and everyone interested in flight should know about it. Simply put, the Breguet range equation tells engineers how far and airplane can fly given a certain set of parameters, and therefore greatly influences the design of modern jet engines and airframes.

A central aspect of flying further for the same amount of fuel is maximising the lift to drag ratio of your wings and airframe. Optimising this ratio gives the maximum aircraft weight (=lift at steady horizontal flight) that can be kept in the air for a given amount of engine thrust (=drag at steady horizontal flight). However, this parameter is not the primary optimum for commercial flight. Instead one wants to fly the furthest possible distance with one fuel filling. Thus to achieve the maximum possible range the quantity to be optimised is the product of flight speed (U) with lift (L) to drag (D) ratio . For most long-haul journeys (~12 hours) the most time consuming part of the journey, and therefore most critical for fuel consumption is the cruise condition. During cruise conditions the band of altitudes that the airliner travels through does not vary greatly such that the local speed of sound

where T is the local static temperature, does not vary greatly. Consequently optimising the Mach Number

times the lift to drag ratio

is virtually the same.

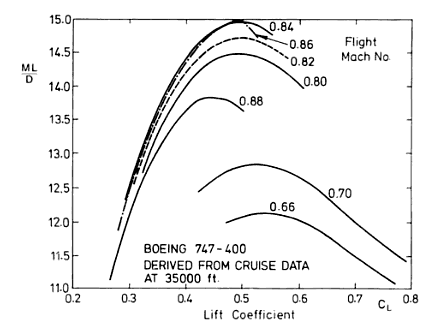

Figure 1 shows experimental data of this parameter versus the lift-coefficient for a Boeing 747-400 at 35,000 ft. At each Mach number L/D rises to a maximum until further increase in lift coefficient leads to stall of the aerofoil. At lower flight speeds the boundary layer separation will occur naturally towards the trailing edge but as we approach a flight speed of Mach 1 shock waves also come into play. The graph shows that for all cruise speeds the optimum value of

occurs at a lift coefficient of about 0.5. The wing area S of an aeroplane is set largely by conditions at take-off and landing, such that it is hard to continually operate at a lift coefficient of 0.5 as the weight and therefore lift of the aeroplane decreases as fuel is burnt. To operate as close to optimum on can therefore decrease v, not very attractive, or decrease the density

by flying at higher altitudes. Large airliners therefore typically start cruise at 31 000 ft or higher and then increase altitude in steps to fly at the optimum

.

The global maximum is achieved for a cruise speed of M = 0.86. Beyond this point can be seen to fall precipitously. Since the air accelerates over the top surface of the aerofoil flight speeds close to Mach 1 can lead to local pockets of supersonic flow over the airflow. At some point these supersonic pockets terminate in a lambda shock wave across which the local air pressure increases to obey the law of thermodynamics. This increase in pressure exacerbates the adverse pressure gradient along the length of the aerofoil, leading to earlier boundary layer separation and an induced increase in drag. Furthermore, the separation caused by shock waves leads to buffeting and control problems. For this reason the typical Mach Number during cruise is set around 0.85.

The next time you fly you could easily check this using one of the onboard screens that display flight data. Take the formula , and set U equal to flight speed in meters/second (= km/hr divided by 3.6), ratio of specific heat capacity

, gas constant

and local temperature T in Kelvin = T in °C +273. Alternatively replacing all values in the equation we get

. Typical flight conditions are 880 km/hr at -60°C giving a Mach Number of 0.83.

The conventional measure of the amount of fuel used compared to the thrust produced is the specific fuel conusmption (SFC). The SFC is the fuel mass-flow rate divided by the thrust produced and therefore has units of kg/(Ns). At cruise, the rate of change of weight (dW/dt) is proportional to the fuel mass-flow rate , , such that,

The negative sign indicates that the weight of the aeroplane is decreasing with time as fuel is burnt. The SFC is,

and since F = D for horizontal cruise we have,

Since W=L for horizontal cruise,

For constant speed U the distance travelled is dx = U*dt, hence

If SFC, U and L/D are constant this expression can be integrated to give the final result,

where are the initial and final weights during cruise. This equation is known as the Breguet Range equation. We discussed before that

should be optimised to increase range. However, it can be noted that the range is inversely proportional to the SFC and since SFC is also a function of the flight speed U the situation is a bit more complicated. In reality the aim is to maximise the ratio of

. Of course SFC also depends on the efficiency of the jet engines, which has been discussed in a series of previous posts (1,2,3). Furthermore, the structural weight is crucial forming a large part of

. Finally the aerodynamic profile of the whole aircraft has to be optimised in order to reduce drag and thereby decrease the thrust F required to overcome it.

References

(1) Cumpsty, N.A. (2003). Jet Propulsion: A Simple Guide to the Aerodynamic and Thermodynamic Design and Performance of Jet Engines. Cambridge University Press.

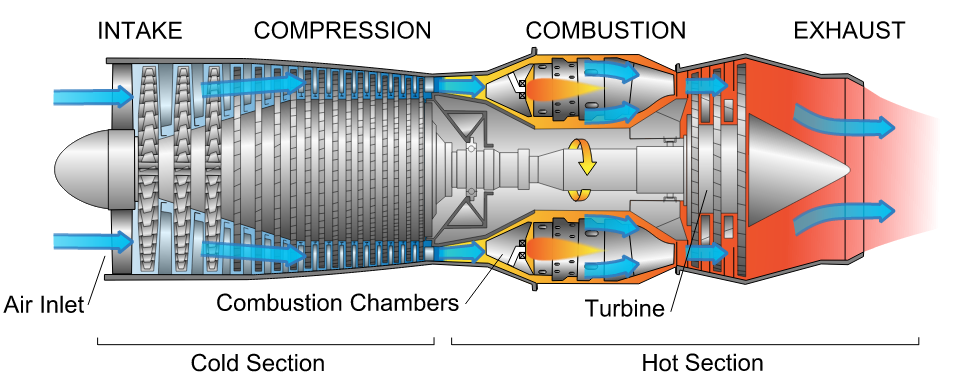

As I described in a previous post, the efficiency of the gas turbine cycle increases as the turbine entry temperature (TET) is increased. Therefore the hotter the combustion gases that enter the first turbine stage the more specific power the jet engine can produce. Of course the TET is bounded by the metallurgical limits of the blade materials, specifically the blade root stress, the creep strain and the melting point of the blade material. The centrifugal stresses at the root increase linearly with the density of the blade material, and linearly with both the square of the rotational speed and the square of the ratio of root-to-tip radius. Creep is the continual and gradual extension of a material under constant load over time. Apart from distorting the physical dimensions and thereby reducing performance of the engine, the induced creep stresses exacerbate the centrifugal operating stresses and will therefore lead to premature failure of the material. A rule of thumb is that the blade life is halved (for a specific blade material and cooling technology) for each 10°C rise in temperature of the metal [1]. The TET has risen from about 1050K in 1944 to about 1750 in the 1994 Rolls-Royce Trent engine. This is partially due to the use of better materials such as Inconel and single-crystal metals with better creep and fatigue properties. However there is a bound to this solution since these nickel-based alloys are typically quite heavy, leading to an increase in centrifugal stresses at the root. Therefore more important in this development has been the technology of channelling of cold compressor air to cool the turbine blades. Using these advanced cooling techniques has allowed engineers to increase the TET beyond the melting point of the blade materials.

In a modern engine around 20% of the compressed air is bled off for cooling and sealing purposes for nozzle guide vanes and turbine blades [1]. This internal air system illustrated in Fig. 1 and Fig. 2. is also used to prevent the any hot mainstream gases from flowing over the heavily stressed blade-attachment discs and control tip clearances between turbine blades and casing. The stators and outer wall of the turbine flow passage use cooling air traveling from the compressor between the combustor and outer engine casing. The turbine rotor blades, disks and inner walls of the turbine flow passage use air bled from the compressor through inner passageways. Since the stators (or nozzle guide vanes) appear before the the first row of rotating blades, the first stage of stators are exposed to the highest temperatures, including local hot-spots from the combustor close by. The temperature at the first rotor stage is then somewhat decreased by dilution of the gases with cooling air, relative velocity effects and power extraction (by gas expansion causing a drop in temperature) from the turbine. In this manner the temperature reduces through each blade row.