Composite Manufacturing – Autoclave Variability

Throughout the last four decades the exploitation of fibre-reinforced plastics (FRP) in engineering structures has been steadily diversifying from sports equipment and high performance racing cars, to helicopters and most recently commercial aeroplanes. Composite materials are essentially a combination of two or more dissimilar materials that are used together in order to combine best properties, or impart a new set of characteristics that neither of the constituent materials could achieve on their own. Engineering composites are typically built-up from individual plies that take the form of continuous, straight fibres (eg. carbon, glass, aramid etc.) embedded in a host polymer matrix (eg. phenolic, polyester, epoxy etc.), which are laminated layer-by-layer in order to built up the final material/structure.

All manufacturing processes are subject to a certain degree of variability. Composite materials differ from most metallic manufacturing routes in that the material is generated at the same time as the structural geometry of the part. In the aerospace industry autoclave components of pre-impregnated reinforcements are the dominant mouldings being used. In this case the hardest variable to control is the thickness dimension and this will be the major concern of this article.

Lean manufacturing calls for variability on thickness expressed as a standard deviation of 1/6th the drawing tolerance – the “6-Sigma” tolerance band – giving a thickness defect rate of 1 in 1,000,000. In reality current thickness defect rates are in the range of 1 in 10 for composite components (1). The biggest influence on laminate thickness is the consolidation pressure. As the consolidation pressure is increased the laminate is compacted more and thus more resin may be bled out of the prepreg. As a result the volume fraction of fiber can vary from just around 50% at 1 bar consolidation to almost 70% at 6 bar. Such large variations in volume fraction will naturally influence the consolidation thickness. The external pressure “felt” by the laminate is not just a function of the target autoclave setting. Insufficient contact between the vacuum bag and the laminate and wrinkles in the bag will greatly reduce the consolidation pressure experienced by the laminate. Since the vacuum bag application is a manual process and the bagging material can be quite flimsy certain amount of wrinkling is inevitable. Thus it can be very difficult to reduce this type of variability and in the worst-case defects such as delaminated plies may occur.

During curing the external temperature is typically ramped up in two stages and held constant in between, the so-called “dwell period”, in order to allow the actual mould temperature to catch-up and ensure full consolidation and cure. During the early parts of the cure the resin viscosity will first reduce as a result of the increasing temperature but then increase suddenly as the mould temperature reaches the gelation point and thus causes the resin to solidify. When the resin viscosity is low internal flows of resin will occur.

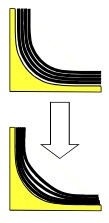

Around corners the difficulty of preventing fibre wrinkling or fibre bridging is added. If plies cannot slip over each other as they consolidate over inside radii, fibre bridging will occur and the laminate will get thicker in the corner. The fibres that bridge the radius will directly react the consolidation pressure leading to a reduced resin pressure beneath the bridged fibres. Resin will, therefore, tend to flow towards this region of bridged fibres but if this does not sufficiently occur high local voidage will result.

Upon consolidation the resin will start to shrink and since it is constrained, the bridged pocket will be exerted under tensile stress. This may cause cracking in the brittle resin and thus cause internal failure before any external load has been applied on the part. Fibre bridging may be reduced by using rollers to press the fabric into the corner or by incorporating slip-lines into the layup. However, especially in the latter case this will complicate the layup and increase manufacturing times.

Equally, if plies cannot slip over external radii then fibre wrinkling or “earing” will occur. Although this will not produce a resin sink the wrinkled area will be voidy and have poorly controlled fibre orientation leading to a reduction in mechanical properties. Fibre wrinkling may also be exacerbated by wrinkles in the vacuum bag over the corner.

Taking the example of the component below the real laminate thickness and target thickness can be widely different. In zone 1 the laminate is likely to be thinner as a result of resin bleeding out of the component unless some sort of resin dam is used. Zones 3 and 5 are likely to be thinner due to resin flow from these areas into the resin sink over the internal radii at zone 4. Ideally the effects of internal and external radii would cancel out at zones 4 and 5 but inaccuracies in the layup or induced tensions in the plies will typically mitigate this. The most critical section of the component is undoubtedly zone 6, where high voidage is very likely due to the difficulty of bleeding sufficient resin into the area and the two adjacent internal radii.

Thickness deviations are only one form of variability. Other defects may stem from part design, manufacturing design, the lay-up process or the autoclave process. To produce reliable components with tightly toleranced dimensions lay-ups are typically made balanced (equal number of ±Angle° plies) and symmetric about the mid-plane in order to avoid thermally induced distortions. Unbalanced or unsymmetric laminates manufactured as plates on flat tools will warp and twist as a result of the different thermal expansion coefficients of different layers. However, if the resin content varies between different plies the thermal properties will naturally vary and the laminate will be unbalanced. For a typical pre-preg the weight/unit area tolerance limits can be up to 5% on both pre-preg and fibre weight, and resin contents may even have a slightly wider tolerance band (1). Considering that resin and fibre contents directly influence the mechanical properties of the composite it can be quite challenging to decrease variability and guarantee reliable components with such a wide tolerance band.

Additional distortions arise if aluminium or steel tooling is used. Metal tools have higher coefficients of thermal expansion than composites and cure in the autoclave can occur at elevated temperatures of typically 180°C. Therefore the tooling will expand more than the composite, putting strains onto the outermost ply. These surface strains may be exacerbated by local features such as a corners and joggles.

A considerable amount of variability around corners is the so-called “spring-in” effect. As the laminate cools down from cure it will contract far more through the thickness than in plane. In order to maintain continuity of the profile without causing residual stresses the corner angles will close up. This can result in changes of corner angle of about 1° for 150°C change in temperature. Other defects such as fibre wrinkling or bridging will worsen this effect. In general it is very difficult to accurately predict what will happen for certain geometries.

In addition, other sources of defects include:

- Surface scratches, depressions and dents

- Delaminations between plies or voids

- Material inclusion within the layup such as a ruler

- Undercure or overcure (burning)

- Tool drop or other impact events that can cause internal resin damage or delaminations

In general most of these defects can be controlled by well-trained and highly motivated factory staff. Engineers and factory management should work together to ensure that all employees involved with the layup and curing process are aware of all possible sources of variability and how to mitigate these. In this respect detailed technical training entrusts more responsibility on the shoulders of employees and gives the staff the deserved recognition of being an important cog in the works of the company. Furthermore, the importance of a well-lit, comfortable working environment and positive atmosphere should not be understated and can go a long way to guaranteeing high-quality mouldings. A well-trained, highly motivated and happy staff is the first line of defence against poor parts.

Next it is important to follow a concurrent design philosophy throughout the development process of a component. Thus the design, stress, manufacturing and quality control engineers must simultaneously work together in order to come up with a solution that fulfils all functional needs but can also be manufactured to a profit without unnecessary defects. The classical philosophy of separately designing a functional component, which is handed to the production engineers, makes manufacturing high-quality laminates incredibly difficult and will incur significant secondary costs.

Finally, specific details of possible sources of variability can then be handled on a case-by-case basis. Thus the component’s shape and type of prepreg to be used will influence the mould material shape design; curing temperature and pressure; possible inclusion of slip lines and laminate stacking sequence as discussed above. In conclusion, manufacturing high-quality laminates for the aerospace industry is not an easy task and is even more daunting considering the size of the current all composite Boeing 787 Dreamliner and Airbus A350 XWB projects. Each design decision must be weighed against the influence on manufacturing process and every little detail is important!

References

(1) Potter, Kevin (1996). An Introduction to Composite Products: Design, Development and Manufacture. Springer, 5th Ed. Chapman & Hall, London.

(2) http://en.wikipedia.org/wiki/File:Delamination-CFRP.jpg

(3) Potter, Kevin (2011). Lecture 4. Basic Processes – Variability and defects. University of Bristol, Bristol.

Related Posts

Sign-up to the monthly Aerospaced newsletter

Recent Posts

- Podcast Ep. #49 – 9T Labs is Producing High-Performance Composite Materials Through 3D Printing

- Podcast Ep. #48 – Engineering Complex Systems for Harsh Environments with First Mode

- Podcast Ep. #47 – Möbius Aero and MμZ Motion: a Winning Team for Electric Air Racing

- Podcast Ep. #46 – Tow-Steered Composite Materials with iCOMAT

- Podcast Ep. #45 – Industrialising Rocket Science with Rocket Factory Augsburg

Topics

- 3D Printing (4)

- Aerodynamics (29)

- Aerospace Engineering (11)

- Air-to-Air Refuelling (1)

- Aircraft (16)

- Autonomy (2)

- Bio-mimicry (9)

- Case Studies (15)

- Composite Materials (25)

- Composites (7)

- Computational Fluid Dynamics (2)

- Contra-Rotation (1)

- Design (2)

- Digitisation (2)

- Drones (1)

- Education (1)

- Electric Aviation (11)

- Engineering (23)

- General Aerospace (28)

- Gliders (1)

- Helicopters (3)

- History (26)

- Jet Engines (4)

- Machine Learning (4)

- Manufacturing (12)

- Military (2)

- Modelling (2)

- Nanomaterials (2)

- NASA (2)

- New Space (11)

- News (3)

- Nonlinear Structures (1)

- Novel Materials/Tailored Structures (14)

- Personal Aviation (5)

- Podcast (45)

- Propulsion (9)

- Renewable Energy (2)

- Renewables (1)

- Rocket Science (17)

- Satellites (8)

- Shape Adaptation (1)

- Smart Materials (1)

- Space (12)

- Space Junk (1)

- Sport Airplanes (2)

- Startup (19)

- STOL (1)

- Structural Efficiency (5)

- Structural Mechanics (1)

- Superalloys (1)

- Supersonic Flight (2)

- Technology (18)

- UAVs (2)

- Virtual Reality (2)

- VTOL (3)

- Privacy & Cookies: This site uses cookies. By continuing to use this website, you agree to their use.

To find out more, including how to control cookies, see here: Cookie Policy