Mark Crouchen is the managing director of Rockwood Composites, a company in the UK that specialises in manufacturing complex composite components using compression and bladder moulding. These manufacturing processes use fibre mats of carbon fibre, glass fibre, Kevlar, or any other material, which are pre-impregnated with a resin matrix and then placed in a mould, where they are cured at elevated temperature with the addition of external or internal pressure.

Mark Crouchen is the managing director of Rockwood Composites, a company in the UK that specialises in manufacturing complex composite components using compression and bladder moulding. These manufacturing processes use fibre mats of carbon fibre, glass fibre, Kevlar, or any other material, which are pre-impregnated with a resin matrix and then placed in a mould, where they are cured at elevated temperature with the addition of external or internal pressure.

The team at Rockwood has been supplying the aerospace, defense, medical and nuclear industries for over 25 years, with customers ranging from Leonardo Helicopters and the McLaren Formula 1 team to Safran and Facebook’s Aquila internet drone. In 2018, Rockwood won the Innovation in Manufacture award at the Composite UK industry event for their innovative use of advanced composite materials on the Tokomak ST40 nuclear fusion reactor. Composite materials have many benefits in terms of their excellent strength and stiffness at low weight. However, there is a common misconception that metal or ceramic components can easily be replaced one-to-one with composite components. The performance of any composite component is closely linked to the quality of the manufacturing process, and designing and manufacturing quality components is an area where Rockwood Composites particularly excel. In this episode of the podcast, Mark and I talk about:

- his background in engineering

- the types of structures that Rockwood Composites manufacture

- why composites manufacturing is a challenge

- and the special solution Rockwood found for the Tokomak ST40 fusion reactor

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multi-scale modelling program, SwiftComp provides an efficient and accurate tool for modelling aerospace structures and materials featuring anisotropy and heterogeneity. SwiftComp quickly calculates the complete set of effective properties needed for use in macroscopic structural analysis. It also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, considering more design options, and arriving at the best solution more quickly. A no-cost Academic Partner Program is now available for eligible universities. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

Paul Withey is the Professor of Casting at the School of Metallurgy and Materials of the University of Birmingham, UK. Before joining the University of Birmingham in 2018, Paul worked at Rolls Royce for 21 years developing new superalloys and manufacturing processes for gas turbine components. As an Engineering Associate Fellow, Paul was a member of a select group of the top 100 specialist engineers across all engineering disciplines within Rolls Royce, and in 2015, Paul and his team were awarded the highest technical award within Rolls-Royce; the Sir Henry Royce Award.

Paul Withey is the Professor of Casting at the School of Metallurgy and Materials of the University of Birmingham, UK. Before joining the University of Birmingham in 2018, Paul worked at Rolls Royce for 21 years developing new superalloys and manufacturing processes for gas turbine components. As an Engineering Associate Fellow, Paul was a member of a select group of the top 100 specialist engineers across all engineering disciplines within Rolls Royce, and in 2015, Paul and his team were awarded the highest technical award within Rolls-Royce; the Sir Henry Royce Award.

Paul’s particular expertise lies in investment casting of aerospace metals, especially of high-temperature superalloys used in the hot turbine stages of modern jet engines. Throughout his career at Rolls-Royce, Paul has developed and optimised manufacturing processes for single-crystal turbine blades with a total of 14 patents to his name. Despite phenomenal advances in materials technology, a number of questions with regard to how the turbine blade shape, materials and process parameters interact remain unanswered, and these questions form the basis of Paul’s ongoing research. In this episode, Paul and I discuss:

- the unique differences between research in academia and industry

- what single-crystal superalloys are and how they are manufactured

- why single-crystal superalloys are a critical technology for modern jet engines

- and the research questions that Paul is currently trying to answer

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multi-scale modelling program, SwiftComp provides an efficient and accurate tool for modelling aerospace structures and materials featuring anisotropy and heterogeneity. SwiftComp quickly calculates the complete set of effective properties needed for use in macroscopic structural analysis. It also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, considering more design options, and arriving at the best solution more quickly. A no-cost Academic Partner Program is now available for eligible universities. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

Oliver Family is the Overall Aircraft Design Leader of the Airbus E-Fan X demonstrator. The E-Fan X is a hybrid-electric technology demonstrator being developed by Airbus, Rolls-Royce and Siemens based on a British Aerospace 146 regional airliner. The driver behind the E-Fan X demonstrator is that current aircraft designs have converged to a near-optimum, and with existing technologies, it is difficult to meet the stringent sustainability goals in terms of CO2/NOX emissions and reductions in noise. New technologies, such as electrification, are therefore required to achieve these goals.

Oliver Family is the Overall Aircraft Design Leader of the Airbus E-Fan X demonstrator. The E-Fan X is a hybrid-electric technology demonstrator being developed by Airbus, Rolls-Royce and Siemens based on a British Aerospace 146 regional airliner. The driver behind the E-Fan X demonstrator is that current aircraft designs have converged to a near-optimum, and with existing technologies, it is difficult to meet the stringent sustainability goals in terms of CO2/NOX emissions and reductions in noise. New technologies, such as electrification, are therefore required to achieve these goals.

As we have seen on other episodes of the podcast, electrification of aircraft is currently a hot topic with new start-up companies promising to disrupt and revolutionise the regional aircraft market. In this environment, one may assume that incumbents like Airbus are too slow to react to a changing technology landscape. As you will hear in this episode, nothing could be further from the truth. The E-Fan X project is structured as a separate entity within Airbus with the explicit mission of challenging Airbus’ legacy business. As you will hear, the consequences of integrating an electric propulsion system on a regional aircraft run much deeper than mere calculations about battery power density and battery longevity. In fact, it’s the secondary effects that we rarely think, hear and read about, such as thermal management of batteries; the interaction between pilots and new control systems; and the challenges of new certification protocols, that are especially challenging. So in this episode, Oliver and I discuss:

- what exactly the E-Fan X demonstrator aims to achieve

- the main technical and economic challenges of electric aircraft

- and how electrification widens the design envelope for engineers

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is sponsored by SAMPE North America. SAMPE is a global professional society that has been providing educational opportunities on advanced materials for more than 70 years. SAMPE’s network of engineers is a key facilitator for the advancement of aerospace engineering by enabling information exchange and synergies between aerospace companies. To find out how SAMPE can help you learn more about advanced materials and process visit SAMPE’s website, or consider attending one of SAMPE’s conferences, such as CAMX, the largest and most comprehensive composites and advanced materials event for products, solutions, networking, and advanced industry thinking.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

- Airbus announcement on the E-Fan X

- Airbus on the future and importance of electric flight (Link 1 and 2)

- Royal Aeronautical Society article on the E-Fan X

- Rolls Royce video on the E-Fan X engines

Today I am speaking to Manuel Schleiffelder, an aerospace engineer based in Vienna, Austria. Manuel has a background in designing and building experimental rockets with the student space team of the Technical University in Vienna, known as the Hound Project. I spoke to Manuel after he returned from a trip to the Black Rock Desert, where the Vienna space team tested their newest two-stage experimental rocket. Manuel has a very broad background in space engineering having worked on projects varying from spacecraft design of lunar landers and systems engineering of rocket propulsion systems, to his newest research project in materials science: metal matrix composites.

Today I am speaking to Manuel Schleiffelder, an aerospace engineer based in Vienna, Austria. Manuel has a background in designing and building experimental rockets with the student space team of the Technical University in Vienna, known as the Hound Project. I spoke to Manuel after he returned from a trip to the Black Rock Desert, where the Vienna space team tested their newest two-stage experimental rocket. Manuel has a very broad background in space engineering having worked on projects varying from spacecraft design of lunar landers and systems engineering of rocket propulsion systems, to his newest research project in materials science: metal matrix composites.

In a classic rocket engine the exhaust gases have a speed limit of exactly Mach 1 (the speed of sound) at the narrowest portion of the nozzle—the so-called choking condition. Since the speed of sound increases with temperature, hotter combustion means the exhaust gases can be expelled from the rocket at greater velocity. While the speed of sound in air at room temperature is typically around 1200 km/hr (745 mph), the speed of sound in the hot exhaust gases of a rocket can be more than 5 times this value. So even though we want our rocket engine to run as hot as possible, there are obvious practical limitations in terms of the ability of materials to withstand these extreme temperatures. For this reason, most rocket engines use some form of cooling to keep the material temperature within reasonable bounds. Manuel is currently developing metal matrix composite materials (carbon fibres embedded within a metal matrix) that are strong enough to withstand the extreme temperatures without the additional mass and complexity of a cooling system. In this episode, Manuel and I talk about

- his background in aerospace engineering

- the rockets that the Vienna student space team are building and testing

- and the advantages and challenges of developing metal matrix composites for rocket engines.

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is sponsored by SAMPE North America. SAMPE is a global professional society that has been providing educational opportunities on advanced materials for more than 70 years. SAMPE’s network of engineers is a key facilitator for the advancement of aerospace engineering by enabling information exchange and synergies between aerospace companies. To find out how SAMPE can help you learn more about advanced materials and process visit SAMPE’s website, or consider attending one of SAMPE’s conferences, such as CAMX, the largest and most comprehensive composites and advanced materials event for products, solutions, networking, and advanced industry thinking.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

On this episode I am speaking to Wenbin Yu, who is a professor at the School of Aeronautics and Astronautics of Purdue University and CTO of AnalySwift, a provider of simulation software for composites. Wenbin has achieved many accolades in both the academic world and in the private sector, and is a fellow of the American Society of Mechanical Engineers. His specialty lies in multi-scale modelling of materials and structures, a topic that we delve into throughout this episode. Material scientists are increasingly inventing materials that are designed from the ground up. This means they take some fundamental building block and then attempt to arrange this building block in an architected manner over multiple length scales.

On this episode I am speaking to Wenbin Yu, who is a professor at the School of Aeronautics and Astronautics of Purdue University and CTO of AnalySwift, a provider of simulation software for composites. Wenbin has achieved many accolades in both the academic world and in the private sector, and is a fellow of the American Society of Mechanical Engineers. His specialty lies in multi-scale modelling of materials and structures, a topic that we delve into throughout this episode. Material scientists are increasingly inventing materials that are designed from the ground up. This means they take some fundamental building block and then attempt to arrange this building block in an architected manner over multiple length scales.

The challenge with these multi-scale architected materials is that the global macro-scale behaviour is influenced by what happens at the micro-scale. And equally, macro-scale deformations can cause damage at the micro-scale. Therefore, modern computational models that are used to design aircraft need to account for what happens at these different length-scales. Traditionally, this is done by constructing different models for each of the length scales, but the problem with these approaches is that they are computationally inefficient. To overcome this, Prof. Yu has developed the Structure Genome, which allows engineers to efficiently aggregate information of the smaller length scales into models at the greater length scales. In this episode, Prof. Yu and I talk about:

- the fundamental difference between a material and a structure

- why multi-scale modelling is important for modern materials and structures

- the Structure Genome

- and how it is being applied to aircraft structures.

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is sponsored by SAMPE North America. SAMPE is a global professional society that has been providing educational opportunities on advanced materials for more than 70 years. SAMPE’s network of engineers is a key facilitator for the advancement of aerospace engineering by enabling information exchange and synergies between aerospace companies. To find out how SAMPE can help you learn more about advanced materials and process visit SAMPE’s website, or consider attending one of SAMPE’s conferences, such as CAMX, the largest and most comprehensive composites and advanced materials event for products, solutions, networking, and advanced industry thinking.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

On this episode of the Aerospace Engineering Podcast I am speaking to Andrew Dunn who is an engineer at the satellite company Alba Orbital in Glasgow, Scotland. Alba Orbital is in the business of building PocketQubes, which are miniaturised satellites mainly used for space science, Earth imaging and space exploration. As the name suggests, PocketQubes are pocket-sized, usually around 5 cm (2 in) cubed and weighing no more than 180 grams. What is more, PocketQubes are typically assembled entirely from commercial off-the-shelf components, driven mostly by the miniaturisation of smartphone electronics, and this makes PocketQubes an ideal low-cost testbed for university labs and smaller startup companies.

On this episode of the Aerospace Engineering Podcast I am speaking to Andrew Dunn who is an engineer at the satellite company Alba Orbital in Glasgow, Scotland. Alba Orbital is in the business of building PocketQubes, which are miniaturised satellites mainly used for space science, Earth imaging and space exploration. As the name suggests, PocketQubes are pocket-sized, usually around 5 cm (2 in) cubed and weighing no more than 180 grams. What is more, PocketQubes are typically assembled entirely from commercial off-the-shelf components, driven mostly by the miniaturisation of smartphone electronics, and this makes PocketQubes an ideal low-cost testbed for university labs and smaller startup companies.

Traditional satellites of the last decades often took so long to develop that by the time they were launched into space, the technology was already out of date. Furthermore, their large size increased launch costs and most components were one-off designs that made them too expensive but for the largest companies. Alba Orbital is currently developing the Unicorn-2 PocketQube platform, which is a modular design that can host different payloads, such as optical equipment, deployable antennas or a radio module, but is built on a foundation of integrated electronics that can serve any need. In this episode, Andrew and I talk about:

- the unique features of PocketQubes

- their components and how they are manufactured

- and Alba Orbital’s future plans for the Unicorn-2 platform

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multiscale modeling program, SwiftComp provides an efficient and accurate tool for modeling aerospace structures and materials featuring anisotropy and heterogeneity. Not only does SwiftComp quickly calculate the complete set of effective properties needed for use in macroscopic structural analysis, it also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, designing earlier in the process, and getting to market more quickly. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

On this episode I am speaking to Max Haot, who is the founder of Launcher, a rocket startup based out of Brooklyn, NY. Launcher was founded in early 2017 and is on a ten-year journey to deliver small satellites to orbit. More specifically, Launcher plans to deliver payloads of up to 300 kg into low-earth orbit cheaper than anyone else in the growing small launcher market; a market specialising on small satellites that will deliver GPS, internet services and earth imaging in the near future.

On this episode I am speaking to Max Haot, who is the founder of Launcher, a rocket startup based out of Brooklyn, NY. Launcher was founded in early 2017 and is on a ten-year journey to deliver small satellites to orbit. More specifically, Launcher plans to deliver payloads of up to 300 kg into low-earth orbit cheaper than anyone else in the growing small launcher market; a market specialising on small satellites that will deliver GPS, internet services and earth imaging in the near future.

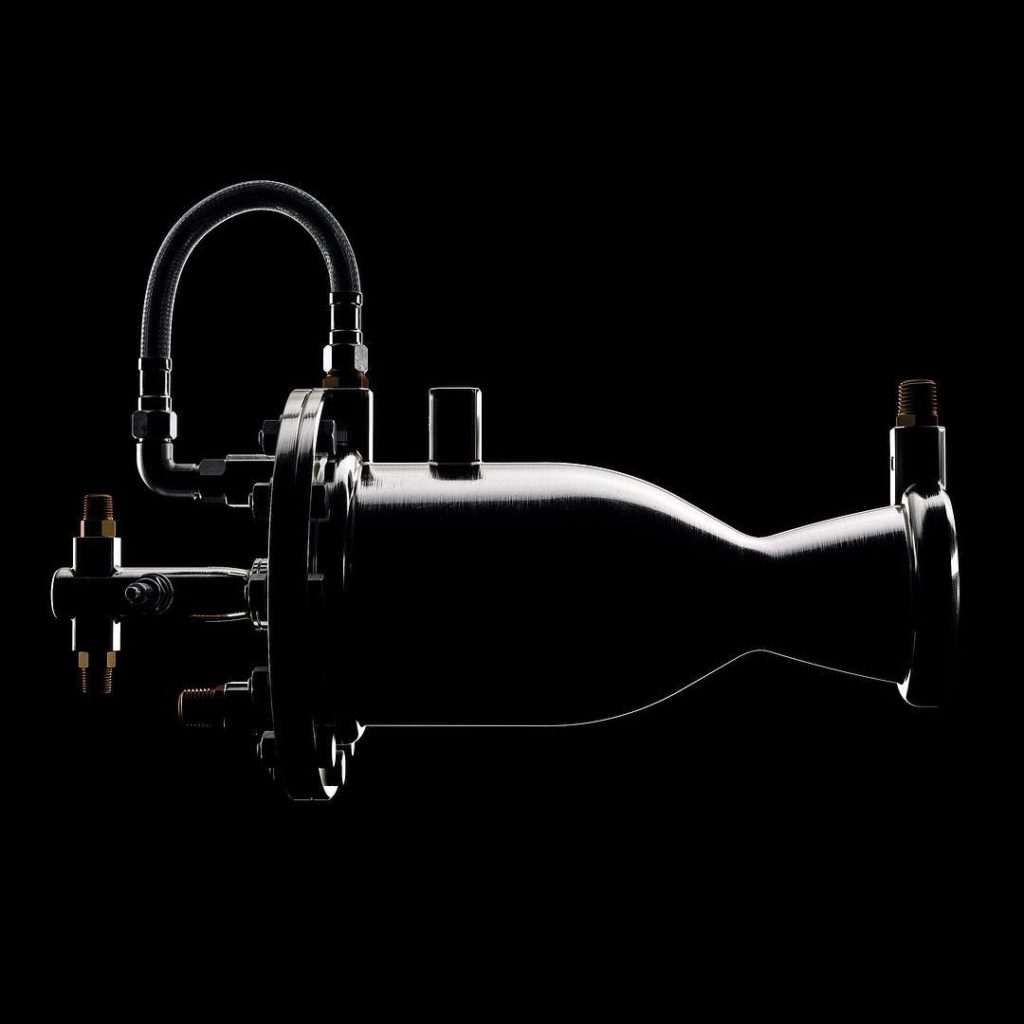

The most difficult part of launching satellites into orbit is building a robust and reliable rocket engine. On top of that, the physics of the rocket equation dictate very stringent constraints on the mass of the rocket and payload. To launch a satellite into low-earth orbit, a typical liquid-oxygen/kerosene rocket is around 95% propellant on the launchpad. So any fuel savings from a more efficient rocket engine can go towards increasing the payload. Launcher has spent the last year working on their proof-of-concept engine, the E-1, and are now in the process of spending the next three years developing the 40x larger E-2 engine. Key to Launcher’s rocket engine is 3D printing and a staged combustion cycle. 3D printing allows for a reduction in parts, faster development times, and easier manufacturing of complex geometries such as integrated cooling channels, which all help to reduce costs. In a staged combustion cycle, a favourite of Soviet rocket engineers, propellant flows through two combustion chambers, a preburner and a main combustion chamber. The pressure produced by igniting a small amount of propellant in the preburner can be used to power the turbo pumps that force the remaining propellant into the main combustion chamber. The addition of the preburner leads to better fuel efficiency, but comes at the cost of greater engineering complexity.

One of the things I love about Launcher is that they face this daunting engineering challenge with the utmost humility, documenting many of their failures and successes online for everyone to see. In this way, anyone can get a glimpse of what it means to build a rocket company from scratch. In this episode of the Aerospace Engineering Podcast you will learn:

- how Max got into the space industry

- the engineering details behind many aspects of the E-1 engine

- the advantages of 3D printing and stage combustion

- and Launcher’s current schedule for developing the full-size E-2 engine

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multiscale modeling program, SwiftComp provides an efficient and accurate tool for modeling aerospace structures and materials featuring anisotropy and heterogeneity. Not only does SwiftComp quickly calculate the complete set of effective properties needed for use in macroscopic structural analysis, it also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, designing earlier in the process, and getting to market more quickly. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

- Launcher Instagram and Twitter

- The Verge visits Launcher for an (explosive) engine test

- Launcher partners with EOS 3D printing

- Static firing test at optimal oxidiser/fuel ratio

- Talk by Max on Launcher’s mission and progress

- Staged combustion cycle (wiki)

- NASA blog on different rocket cycles

- History of rocket science

- Rocket operating principles and the rocket equation

On this episode I am speaking to Nick Sills who is the founder of Contra Electric Propulsion Ltd. Nick’s engineering background is in developing underwater propulsion systems for the offshore oil and gas industry. He has designed products ranging from a hydraulically powered excavator for pipeline route trenching, to the world’s biggest deep water excavator. He received a Queen’s Award for Technological Achievement for the “Jet Prop” tool, a 5 m diameter propeller that is powered by ejecting high pressure seawater from its propeller blades.

On this episode I am speaking to Nick Sills who is the founder of Contra Electric Propulsion Ltd. Nick’s engineering background is in developing underwater propulsion systems for the offshore oil and gas industry. He has designed products ranging from a hydraulically powered excavator for pipeline route trenching, to the world’s biggest deep water excavator. He received a Queen’s Award for Technological Achievement for the “Jet Prop” tool, a 5 m diameter propeller that is powered by ejecting high pressure seawater from its propeller blades.

Nick founded his most recent company, Contra Electric Propulsion, to develop a contra-rotating propeller system for the light aircraft market. Contra-rotating propeller systems typically use two propellers mounted in series that spin in opposite directions. The fact that props are spinning in both directions alleviates many of the attitude and control problems when flying aircraft.

Contra-rotation has rarely found its way onto modern, gas-powered aircraft because the variable-pitch requirement for efficient operation has made the system overly expensive, complex and maintenance intensive. By changing the power source from fossil fuels to electrons, however, many components of the modern aircraft can be designed differently. With new electric motors it is now possible to build a much simpler, fixed-pitch, contra-rotating propulsion system for light aircraft.

As an aerobatic pilot, Nick immediately realised the massive advantages of instantaneous torque delivery and reversible thrust that electric motors can provide. That’s why he believes that the next big advance in light aircraft propulsion will be a battery-powered, twin motor, contra-rotating system with fixed-pitch propellers. Since this has now become technically feasible, he is privately building one to prove it.

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multiscale modeling program, SwiftComp provides an efficient and accurate tool for modeling aerospace structures and materials featuring anisotropy and heterogeneity. Not only does SwiftComp quickly calculate the complete set of effective properties needed for use in macroscopic structural analysis, it also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, designing earlier in the process, and getting to market more quickly. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

On this episode I am speaking to Thomas Pfammatter, who is the co-founder of the Swiss electric aircraft startup Dufour Aerospace. Dufour is currently designing an electric aircraft with vertical take-off and landing (VTOL) capabilities for the urban and rural transport market. The promise of their current aircraft, the aEro 2, is that with VTOL capabilities it can take-off and land pretty much anywhere, which can considerably reduce travel times, especially to places that are difficult to reach by car or train.

On this episode I am speaking to Thomas Pfammatter, who is the co-founder of the Swiss electric aircraft startup Dufour Aerospace. Dufour is currently designing an electric aircraft with vertical take-off and landing (VTOL) capabilities for the urban and rural transport market. The promise of their current aircraft, the aEro 2, is that with VTOL capabilities it can take-off and land pretty much anywhere, which can considerably reduce travel times, especially to places that are difficult to reach by car or train.

There is a long-standing compromise in aviation between taking-off vertically, and being able to travel fast horizontally. Dufour Aerospace believes that with electric propulsion it is possible to combine these two worlds. To achieve this, Dufour are using a tilt-wing design fitted with two propellers. The wing and attached propellers can pivot around a hinge between the horizontal and vertical planes, and thereby provide exceptional lift, stability and control characteristics even in slow flight. Dufour have proven their electrical aviation ambitions with the aEro1 aerobatic aircraft and are currently in the process of developing the tilt-wing aEro 2 airplane. In this episode you will learn about many of the details behind Dufour’s technology such as:

- the tilt-wing concept and the tail fan used for pitch control

- the aerodynamic importance of the vortex ring state

- the future of regional travel and how Dufour hopes to influence this space

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode is brought to you by AnalySwift. Do you work in the design and analysis of aerospace structures and materials? If so, AnalySwift’s innovative engineering software SwiftComp may be the solution you’re seeking. Used either independently for virtual testing of aerospace composites or as a plugin to power conventional FEA codes, SwiftComp delivers the accuracy of 3D FEA in seconds instead of hours. A general-purpose multiscale modeling program, SwiftComp provides an efficient and accurate tool for modeling aerospace structures and materials featuring anisotropy and heterogeneity. Not only does SwiftComp quickly calculate the complete set of effective properties needed for use in macroscopic structural analysis, it also accurately predicts local stresses and strains in the microstructure for predicting strengths. Find out how others in composites are saving time while improving accuracy, designing earlier in the process, and getting to market more quickly. For a free trial, visit analyswift.com. SwiftComp: Right results. Right away.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

Robin Hague is the Lead Engineer at the rocket startup Skyrora based in Edinburgh, Scotland. The goal of Skyrora is to provide a dedicated launch vehicle for small satellites. It has never been cheaper to build small satellites that provide imaging and communication services, and this sector of the space economy is expected to grow rapidly over the coming years. The UK is a world leader in the small satellite business—with Glasgow in Scotland building more satellites than any other city in Europe—but there is currently a shortfall of dedicated launchers for these satellite companies. Skyrora hopes to serve this market by launching rockets from Norther Scotland, which has great access to polar and sun-synchronous orbits. In this episode of the Aerospace Engineering podcast Robin and I talk about:

Robin Hague is the Lead Engineer at the rocket startup Skyrora based in Edinburgh, Scotland. The goal of Skyrora is to provide a dedicated launch vehicle for small satellites. It has never been cheaper to build small satellites that provide imaging and communication services, and this sector of the space economy is expected to grow rapidly over the coming years. The UK is a world leader in the small satellite business—with Glasgow in Scotland building more satellites than any other city in Europe—but there is currently a shortfall of dedicated launchers for these satellite companies. Skyrora hopes to serve this market by launching rockets from Norther Scotland, which has great access to polar and sun-synchronous orbits. In this episode of the Aerospace Engineering podcast Robin and I talk about:

- the history of British rocketry (the Black Arrow)

- the benefits of using hydrogen peroxide as a propellant

- the role of 3D printing in modern rocket engines

- and the future of Skyrora.

If you enjoy the Aerospace Engineering Podcast you can support it by leaving a review on iTunes or by supporting it directly on Patreon, where patrons of the podcast receive exclusive behind-the-scenes content and special episodes. Thanks a lot for listening!

Podcast: Play in new window | Download | Embed

Subscribe: Apple Podcasts | TuneIn | RSS

This episode of the Aerospace Engineering Podcast is sponsored by SAMPE North America. SAMPE is a global professional society that has been providing educational opportunities on advanced materials for more than 70 years. SAMPE’s network of engineers is a key facilitator for the advancement of aerospace engineering by enabling information exchange and synergies between aerospace companies. To find out how SAMPE can help you learn more about advanced materials and process visit SAMPE’s website, or consider attending one of SAMPE’s conferences, such as CAMX, the largest and most comprehensive composites and advanced materials event for products, solutions, networking, and advanced industry thinking.

This episode is also sponsored by StressEbook.com, which is an online hub for you if you are interested in aerospace stress engineering. StressEbook.com provides world-class engineering services and online courses on the stress analysis of aircraft structures, as well as a free ebook and blog. No matter if you’re a junior or senior structural analyst, stressEbook.com provides you with the skills and know-how to become a champion in your workplace.

Selected Links from the Episode

- Skyrora: Webpage and Twitter feed

- Skyrora and 3D printing

- Hydrogen peroxide as propellant:

- Plans to launch from Northern Scotland

- The British are coming…for the rocket-launching industry

- The Black Arrow rocket: (1, 2) and cross-section drawing

Sign-up to the monthly Aerospaced newsletter

Recent Posts

- Podcast Ep. #49 – 9T Labs is Producing High-Performance Composite Materials Through 3D Printing

- Podcast Ep. #48 – Engineering Complex Systems for Harsh Environments with First Mode

- Podcast Ep. #47 – Möbius Aero and MμZ Motion: a Winning Team for Electric Air Racing

- Podcast Ep. #46 – Tow-Steered Composite Materials with iCOMAT

- Podcast Ep. #45 – Industrialising Rocket Science with Rocket Factory Augsburg

Topics

- 3D Printing (4)

- Aerodynamics (29)

- Aerospace Engineering (11)

- Air-to-Air Refuelling (1)

- Aircraft (16)

- Autonomy (2)

- Bio-mimicry (9)

- Case Studies (15)

- Composite Materials (25)

- Composites (7)

- Computational Fluid Dynamics (2)

- Contra-Rotation (1)

- Design (2)

- Digitisation (2)

- Drones (1)

- Education (1)

- Electric Aviation (11)

- Engineering (23)

- General Aerospace (28)

- Gliders (1)

- Helicopters (3)

- History (26)

- Jet Engines (4)

- Machine Learning (4)

- Manufacturing (12)

- Military (2)

- Modelling (2)

- Nanomaterials (2)

- NASA (2)

- New Space (11)

- News (3)

- Nonlinear Structures (1)

- Novel Materials/Tailored Structures (14)

- Personal Aviation (5)

- Podcast (45)

- Propulsion (9)

- Renewable Energy (2)

- Renewables (1)

- Rocket Science (17)

- Satellites (8)

- Shape Adaptation (1)

- Smart Materials (1)

- Space (12)

- Space Junk (1)

- Sport Airplanes (2)

- Startup (19)

- STOL (1)

- Structural Efficiency (5)

- Structural Mechanics (1)

- Superalloys (1)

- Supersonic Flight (2)

- Technology (18)

- UAVs (2)

- Virtual Reality (2)

- VTOL (3)

- Privacy & Cookies: This site uses cookies. By continuing to use this website, you agree to their use.

To find out more, including how to control cookies, see here: Cookie Policy